Film Faced Plywood Application Case

Project Overview:

A major metropolitan city undertook the construction of a towering commercial complex, encompassing multiple high-rise structures and intricate architectural features. The project demanded materials that could withstand the rigors of construction, provide a flawless finish, and ensure longevity. Film Faced Plywood emerged as the material of choice for the formwork system, where it would be exposed to the demanding conditions of concrete casting.

Formwork Construction:

The application of Film Faced Plywood in formwork construction proved instrumental in shaping the complex structures of the commercial complex. Formwork, the temporary mold into which concrete is poured, plays a pivotal role in determining the final appearance and structural integrity of a building. FFP excelled in this role due to its unique characteristics.

Key Features of Film Faced Plywood in Construction:

High Load-Bearing Capacity: Film Faced Plywood, with its strong and dense core, demonstrated exceptional load-bearing capacity. This was crucial for supporting the weight of wet concrete during the casting process, ensuring structural stability.

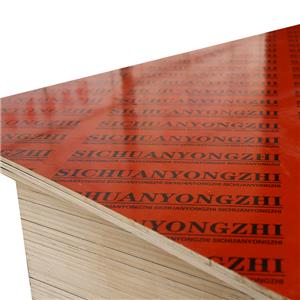

Durability Under Harsh Conditions: The external layer of the plywood, coated with a phenolic film, provided a robust and durable surface. This layer not only resisted the abrasive nature of concrete but also protected the plywood from moisture, extending its lifespan and maintaining its structural integrity.

Smooth Concrete Finish: The smooth surface of Film Faced Plywood translated into a flawless concrete finish. This was particularly important for the visible surfaces of the commercial complex, contributing to the aesthetic appeal of the finished structures.

Efficiency in Construction:

The ease of handling and cutting Film Faced Plywood streamlined the construction process. Its flexibility allowed for the creation of customized formwork shapes, meeting the complex architectural requirements of the project. The quick assembly and disassembly of the formwork, thanks to FFP's adaptability, contributed to overall construction efficiency.

Cost-Effectiveness and Reusability:

While Film Faced Plywood is an initial investment, its cost-effectiveness became apparent through its reusability. The plywood panels, with proper care and maintenance, could be reused for multiple concrete casting cycles, reducing the overall cost of formwork materials for the project.

Environmental Considerations:

Recognizing the importance of sustainability, the project management ensured that the Film Faced Plywood used adhered to environmental standards. This included sourcing plywood from responsibly managed forests and selecting products with low formaldehyde emissions.

Project Success and Future Prospects:

The application of Film Faced Plywood proved to be a resounding success in the construction of the commercial complex. The structures stood as a testament to the material's strength, durability, and contribution to efficient construction practices. The success of this project has spurred interest in further exploring the applications of Film Faced Plywood in upcoming construction endeavors, highlighting its indispensable role in shaping the skylines of modern cities.

In conclusion, the case of the commercial complex construction vividly illustrates how Film Faced Plywood has become a cornerstone in the construction industry. Its robust characteristics, coupled with efficiency and environmental considerations, position it as a go-to material for demanding construction projects worldwide. As technology advances, Film Faced Plywood is likely to continue playing a pivotal role in shaping the future of construction.