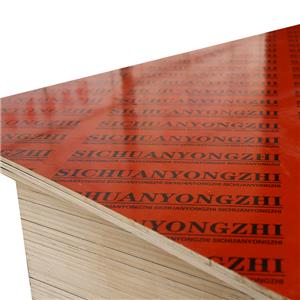

11mm Hardwood Osb2 Waterproof OSB

Brand YZY

Product origin Linyi

Delivery time 7~20 Days

Supply capacity 1000CBM/Week

Overview

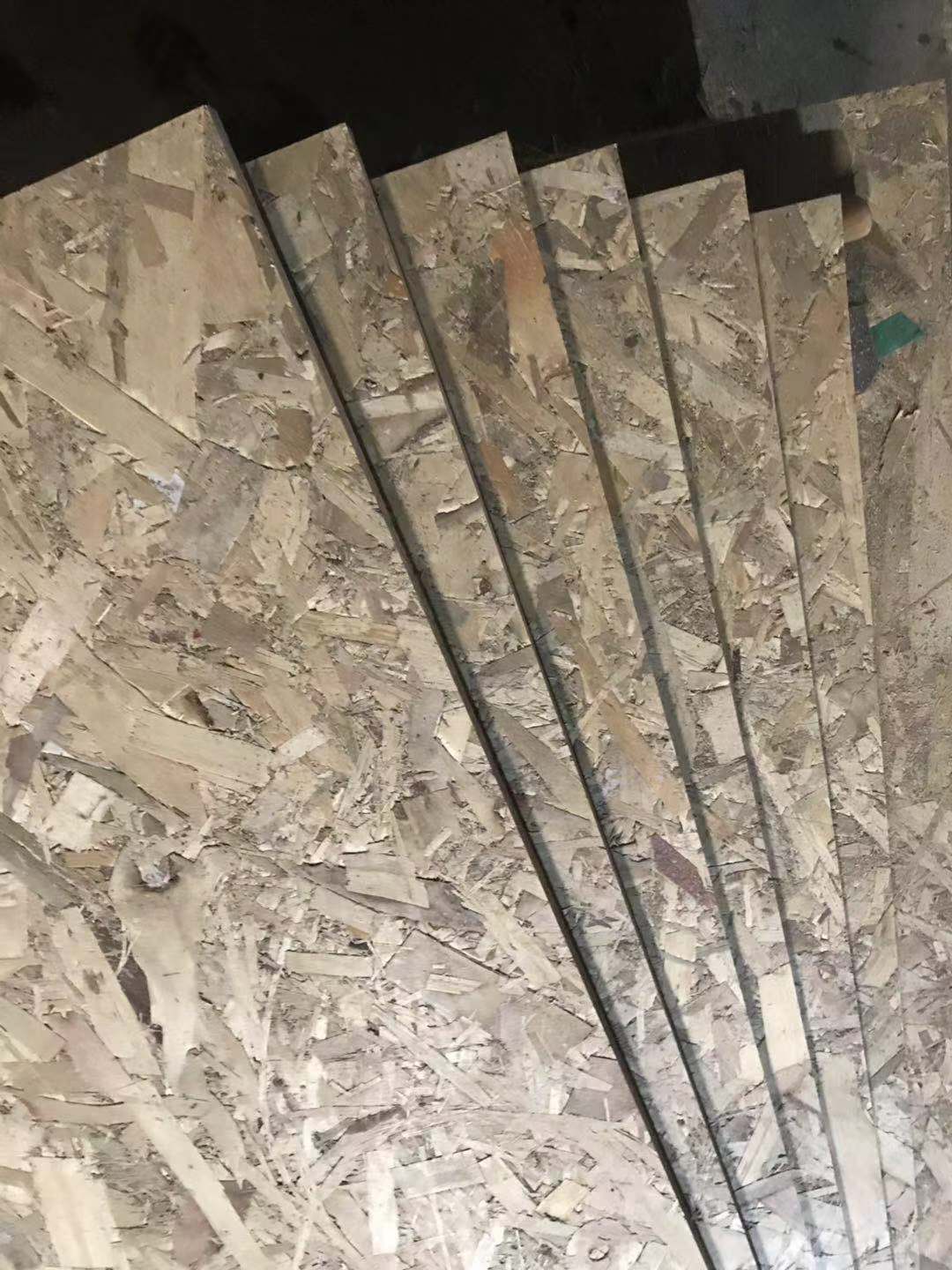

Type:Flakeboards

Warranty:3 years

After-sale Service:Online technical support, Onsite Installation

Capability:graphic design, 3D model design

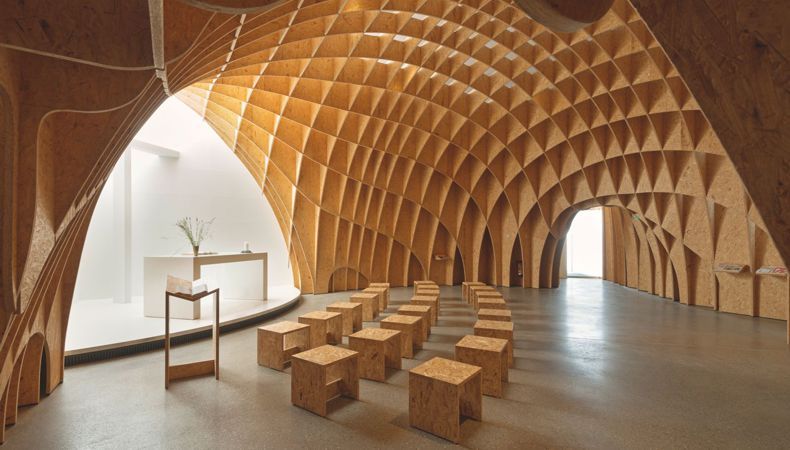

Application:Hotel, Office Building

Design Style:Contemporary

Place of Origin:China

Model Number:OSB board

Usage:Indoor &Outside

Surface Finishing:Finished

Grade:Excellent

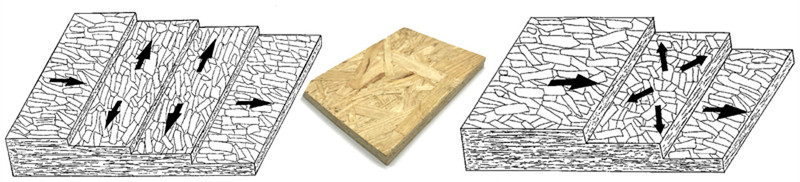

Slab Structure:3-Layer Structure Boards

Product name:OSB

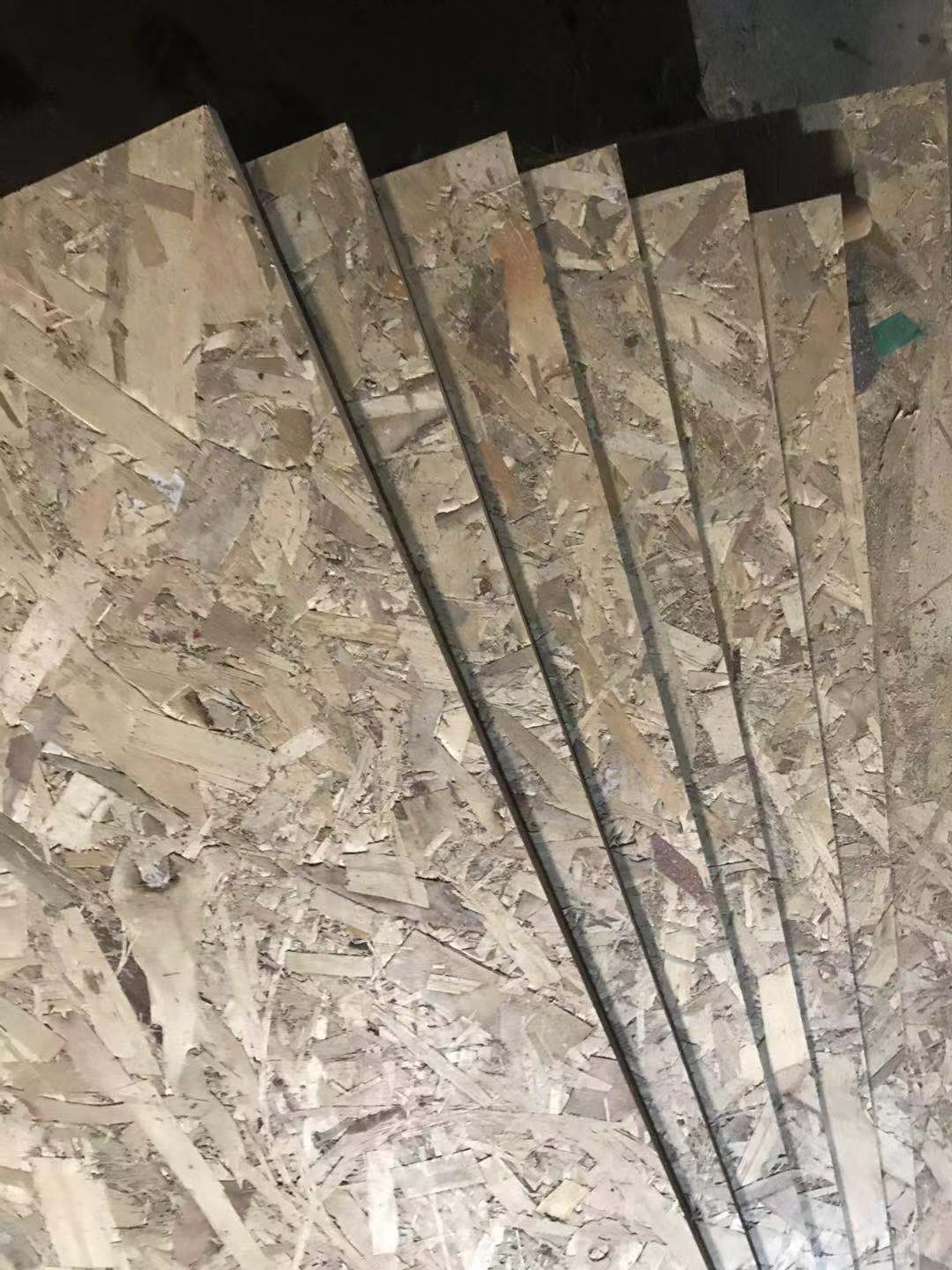

Thickness:9~25mm

OSB Board For Construction Flakeboards Particle Board

Name | OSB Formwork Board | |||

Brand | YZY | |||

Size | 1220*2440,1250*2500mm or upon request | |||

Thickness tolerance | 8-25mm or upon request | ±0.2mm | ||

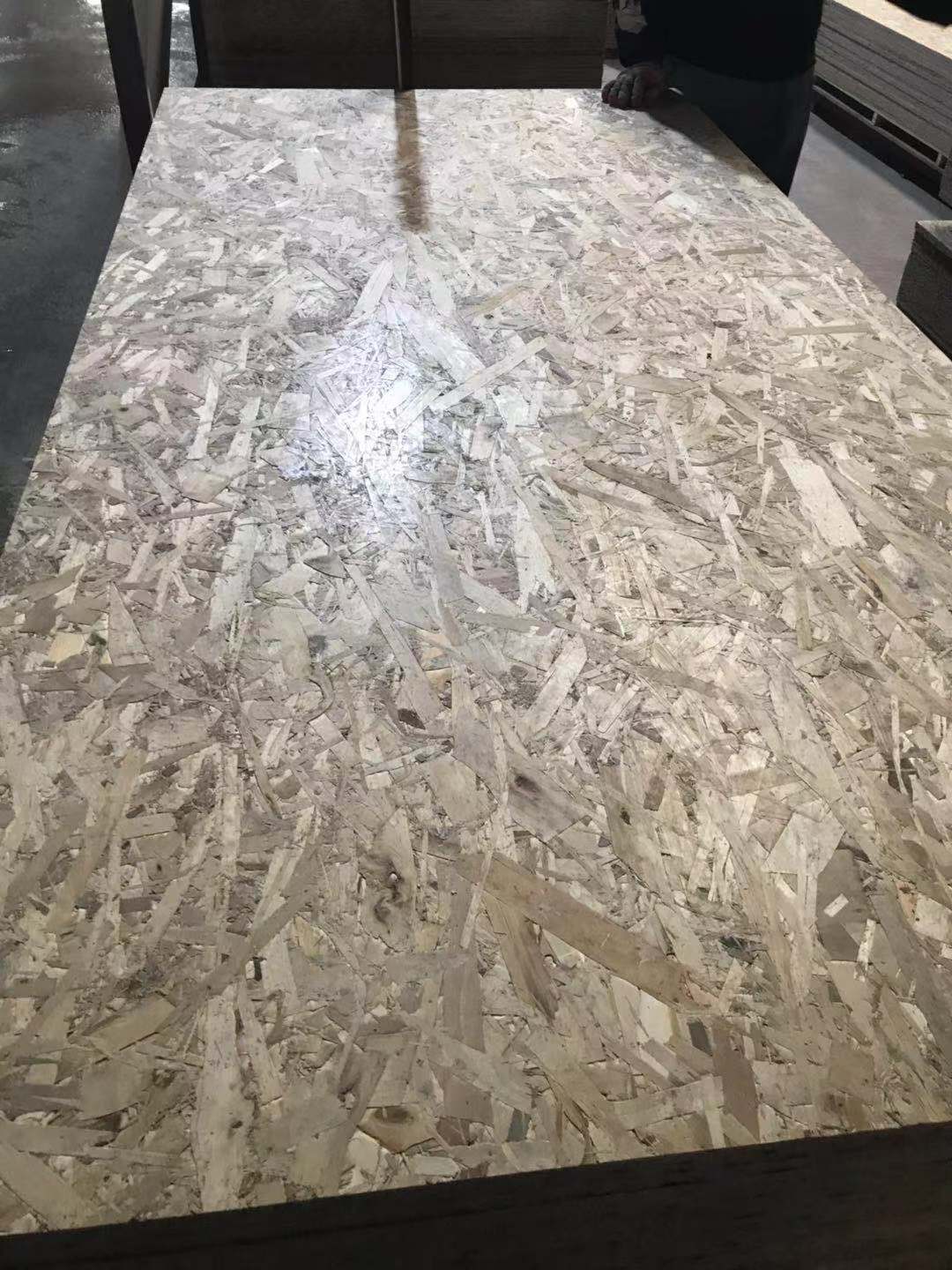

Formaldehyde Emission Level | Carb,E0,E1,E2 | |||

Glue | MR,Melamine,phenolic WBP,PMDI | |||

Density | 600-720kg/m3. | |||

Usage | Real estate construction /formwork panel | |||

Package | outer packing: Pallets are covered with plywood or carton boxes and strong steel belts | |||

Certification | CE, ISO, FSC, CARB | |||

elivery time | Within 2-3 weeks upon down payment or upon opening of L/C | |||

Min Order | 1*20'ft | |||

PAYMENT TERM | TT or L/C | |||

Supply ability | 50000 M3/per month | |||

Marks | mrearkets are using OSB board to replace film faced plywood for cheaper price consideration. Our OSB board has different grades to satisfy different quality requirements.Basically, OSB has lower formaldehyde emission and can be easily cut/nailed/groove/planed etc. High-quality OSB can have very tight core construction and hence board strength can be quite strong too. We can also offer film faced OSB for construction purposes. For more details please contact us. | |||

Is OSB Board Waterproof?

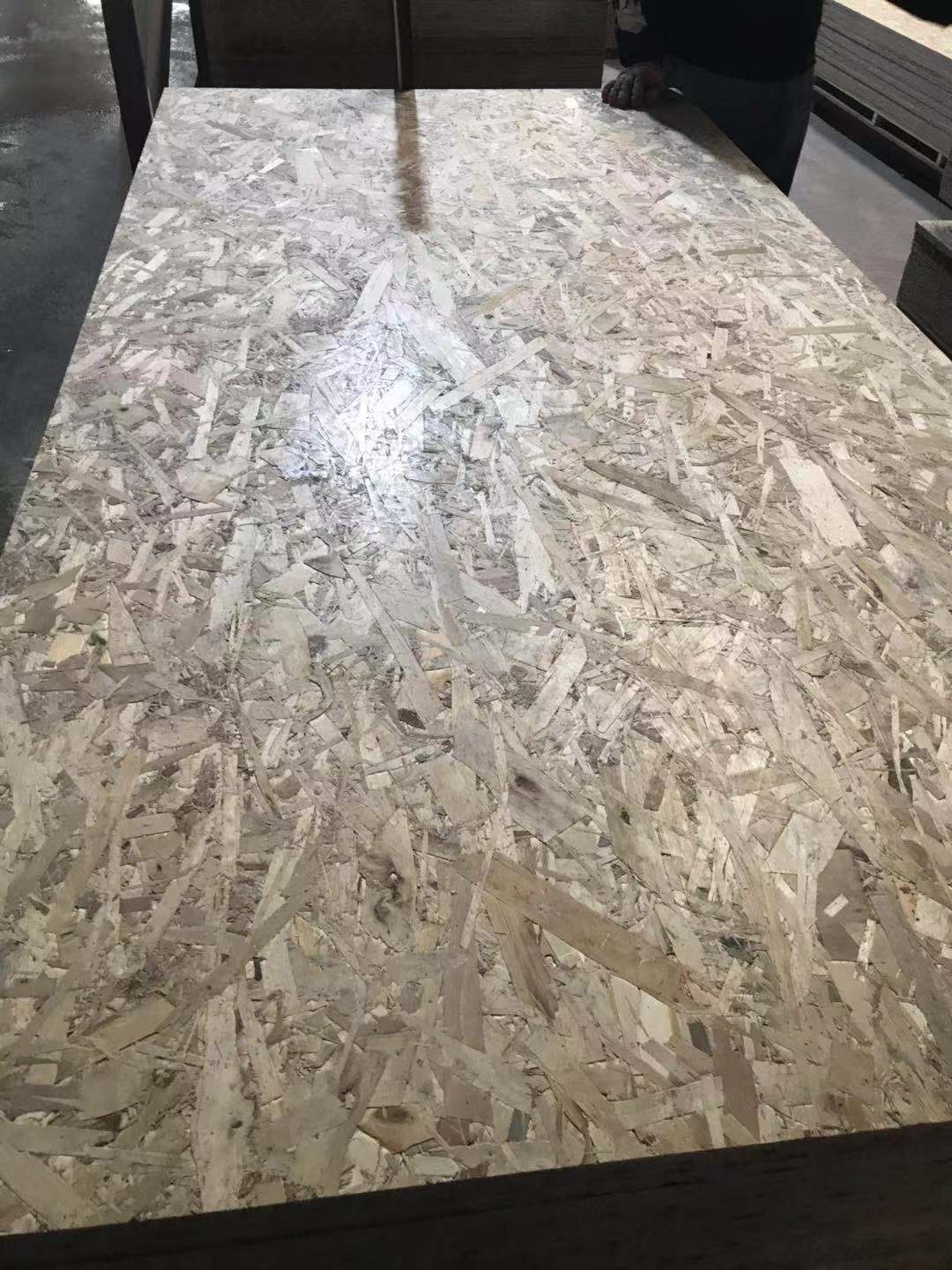

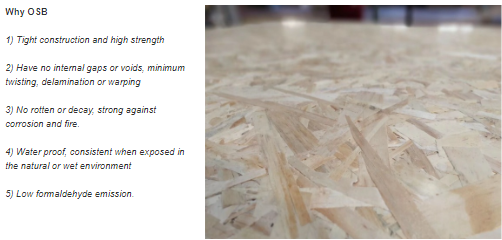

Oriented Strand Board (OSB) is widely used in construction, but its waterproof properties are often misunderstood. In its natural state, OSB is not fully waterproof and requires additional protection when exposed to external conditions. However, there are different grades of OSB, each with varying degrees of moisture resistance that can make them suitable for different applications.

OSB Grades and Their Moisture Resistance

OSB is manufactured according to the European Standard BS EN 300, which classifies the material into different grades based on its ability to resist moisture and its intended use.

OSB2 (OSB/2): This grade is designed strictly for use in dry, internal conditions. It is not suitable for environments with high humidity or exposure to water. OSB2 is commonly used in applications such as interior walls and furniture but should not be used for external purposes without significant moisture protection.

OSB3 (OSB/3): While this grade can be used in humid conditions, it is still not fully waterproof. OSB3 is capable of withstanding higher moisture levels in the air, making it suitable for load-bearing applications such as wall and roof sheathing. However, OSB3 must be protected from direct exposure to rain or water, as it is not designed to handle long-term exposure to liquid water.

The Need for Waterproof OSB

In certain scenarios, OSB is exposed to external conditions, which introduces the risk of water damage. Even engineered wood products like OSB are vulnerable to moisture over time, especially when subjected to prolonged exposure. Without proper protection, OSB boards can absorb moisture, causing the wood strands, especially those on the surface or edges, to swell or shrink. Eventually, water can penetrate deep into the layers, compromising the board's structural integrity.

Some common applications where OSB is exposed to external elements include:

Site hoarding and fencing: Temporary barriers that require boards to be exposed to the weather.

Wall and roof sheathing: OSB is often used in structural insulated panels (SIPs), but if construction delays leave the OSB exposed to the elements, it could be damaged by rain.

In both cases, waterproofing becomes essential to ensure the long-term durability of the material.

Waterproofing Solutions for OSB

Waterproofing OSB involves several methods to enhance its resistance to moisture. Here are a few commonly used techniques:

Paint and Coatings: Applying a coat of waterproof paint or a protective varnish is one way to protect OSB from moisture. However, paint alone cannot make OSB fully waterproof. Priming the board before painting is crucial, as it prevents excessive paint absorption by the wood. The paint can add a layer of defense against water, but should be sealed with a protective coating to increase its effectiveness.

Traditional Waterproofing Membranes: These are often installed over OSB during construction, creating a barrier between the board and external moisture. However, this process can be time-consuming, and its effectiveness can be compromised if the installation is delayed or if poor weather conditions prevent timely application.

Arctek Performance Overlay Technology: A modern, efficient alternative to on-site waterproofing, Arctek overlay is applied during the OSB manufacturing process. This thermally fused layer forms a durable, waterproof surface that is strongly bonded to the OSB. Boards treated with Arctek are shipped to construction sites already protected, eliminating the risk of exposure during installation and ensuring consistent waterproofing performance.

When is Waterproof OSB Required?

Waterproof OSB is often necessary in projects where the boards will be exposed to moisture. While OSB3 can withstand humidity and occasional light rain, prolonged exposure to liquid water, especially heavy rainfall, can damage the board. Therefore, a weatherproofing treatment is advisable for any situation where OSB may be exposed to extended moisture, such as:

Roof sheathing: Although OSB3 can handle some moisture, heavy rain can cause swelling and weaken the roof’s integrity. For this reason, OSB used in roofing should be weatherproofed.

Subflooring: Water exposure in subflooring can lead to significant damage. Waterproof OSB can help mitigate moisture-related risks in areas where floors may be exposed to humidity or accidental water spills.

It is important to note that humidity and liquid water exposure are not the same. While OSB3 is rated for humid conditions, this typically refers to airborne moisture rather than direct exposure to rain or standing water.

Can Painted OSB Be Exposed to Rain?

While painting OSB provides an extra layer of defense against moisture, it does not fully waterproof the material. Painted OSB can resist some light moisture, but should not be left in the rain for long periods. Priming before painting is essential, as OSB tends to absorb large quantities of paint, reducing its effectiveness as a waterproofing solution.

If you plan to use OSB outdoors or in areas where it will be exposed to rain, it is crucial to apply additional waterproofing measures, such as protective coatings or membranes. However, the quality of these applications can vary based on factors like weather conditions at the time of application, making them less reliable than factory-applied solutions like Arctek overlays.

Conclusion

In its natural state, OSB is not waterproof, but with the right treatment, it can be made resistant to moisture. While OSB2 is restricted to dry environments, OSB3 can be used in humid conditions, although it still requires protection from rain and direct water exposure. Waterproofing techniques like paint, coatings, membranes, or Arctek overlays are essential for protecting OSB in external applications. For projects where weatherproofing is critical, factory-applied solutions tend to offer the most consistent and reliable protection, ensuring the long-term durability of OSB in construction.