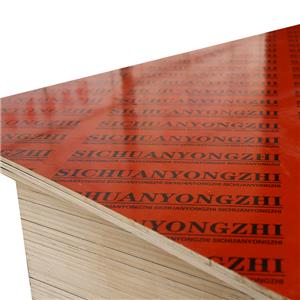

Melamine Faced MDF Board For Cabinets

Brand YZY

Product origin CHINA

Delivery time 15-20 days after recived the deposit

Supply capacity 10000 Cubic Meter/Per Month

Laminated MDF board

Medium-density fibreboard (MDF) is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibres, often in a defibrator, combining it with wax and a resin binder, and forming panels by applying high temperature and pressure. MDF is generally denser than plywood. It is made up of separated fibres, but can be used as a building material similar in application to plywood. It is stronger and much denser than particle board.

Product Introduction

Name | Melamine MDF ,Veneer MDF | ||

Size | 1220x2440mm, 915x2135mm or as clients requirement | ||

Thickness | 2~25mm | ||

Thickness Tolerance | +/-0.2mm | ||

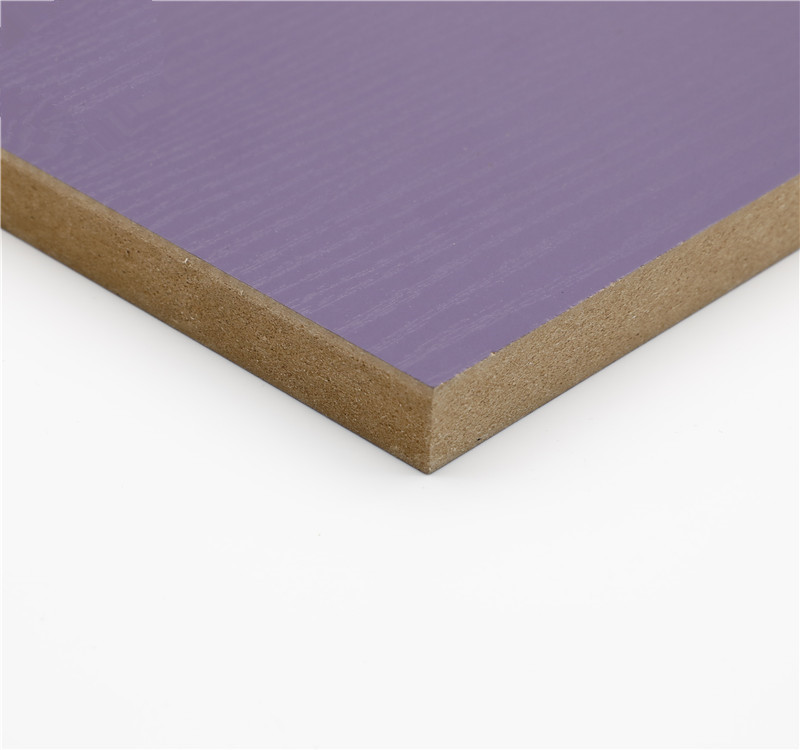

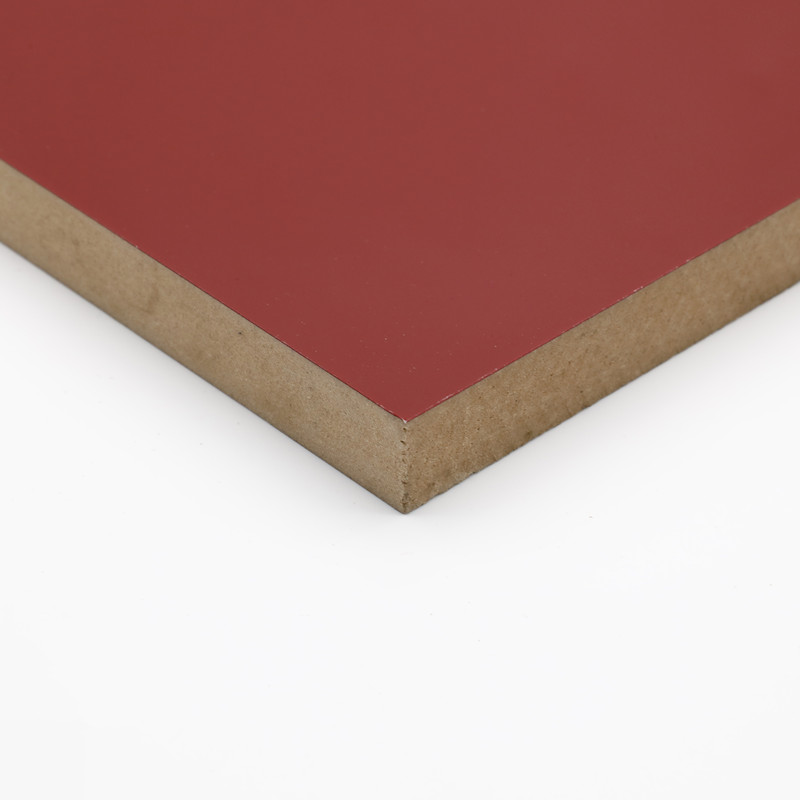

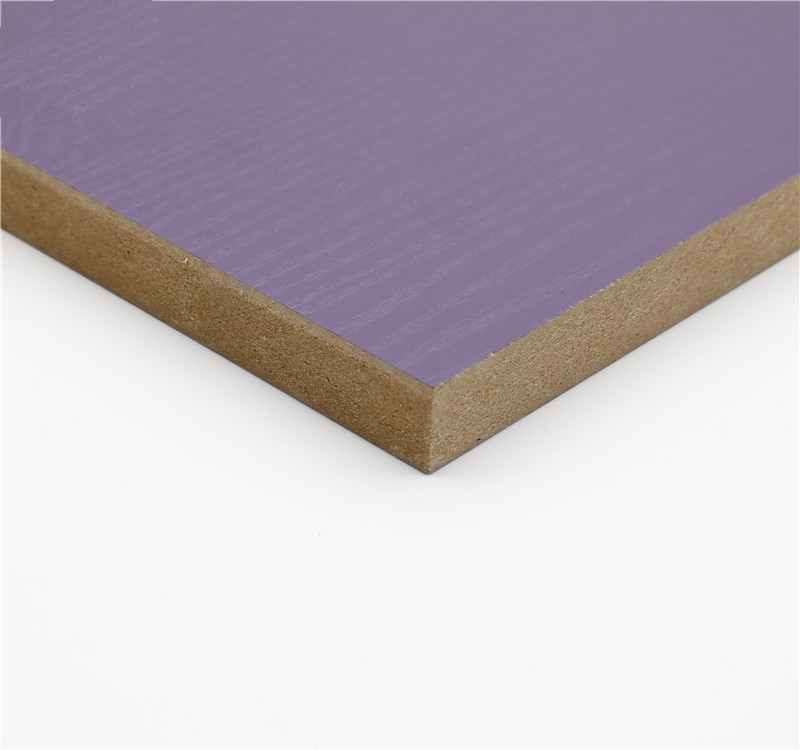

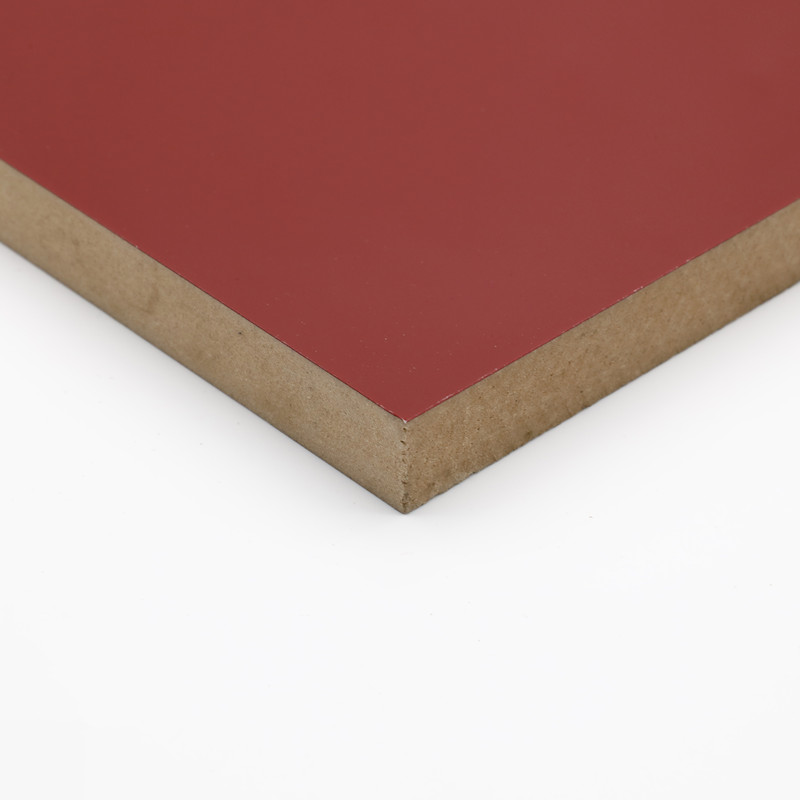

Face/Back | Melamine Faced (one side or both side melamine faced) White, Blue, Pink, Grey, Biege glossy white ,Biege embossed | ||

Surface Treatment | Matt, textured, glossy, embossed or magic | ||

Melamine Paper Color | -Solid color (such as grey, white, black, red, blue, orange, green, yellow, etc.) -Wood grain (such as beech, cherry, walnut, teak, oak, maple, sapele, wenge, etc.) -Cloth grain -Marble grain. -More than 300 kinds color are available. | ||

Melamine Paper Gram | 80~120g/m2 | ||

Core Material | Wood fiber (poplar, pine or combi), MDF, Chipboard | ||

Glue | E0, E1 or E2 | ||

Grade | A grade or as clients requirement | ||

Density | 500~700kg/m3 (thickness>6mm), 830~900kg/m3 (thickness≤6mm) | ||

Technical Parameters | Moisture Content | ≤8% | |

Water Absorption | ≤12% | ||

Modulus of Elasticity | ≥2500Mpa | ||

Static Bending Strength | ≥22Mpa | ||

Surface Bonding Strength | ≥1.20Mpa | ||

Internal Bonding Strength | ≥0.55Mpa | ||

Screw Holding Ability | Face | ≥1300N | |

Edge | ≥800N | ||

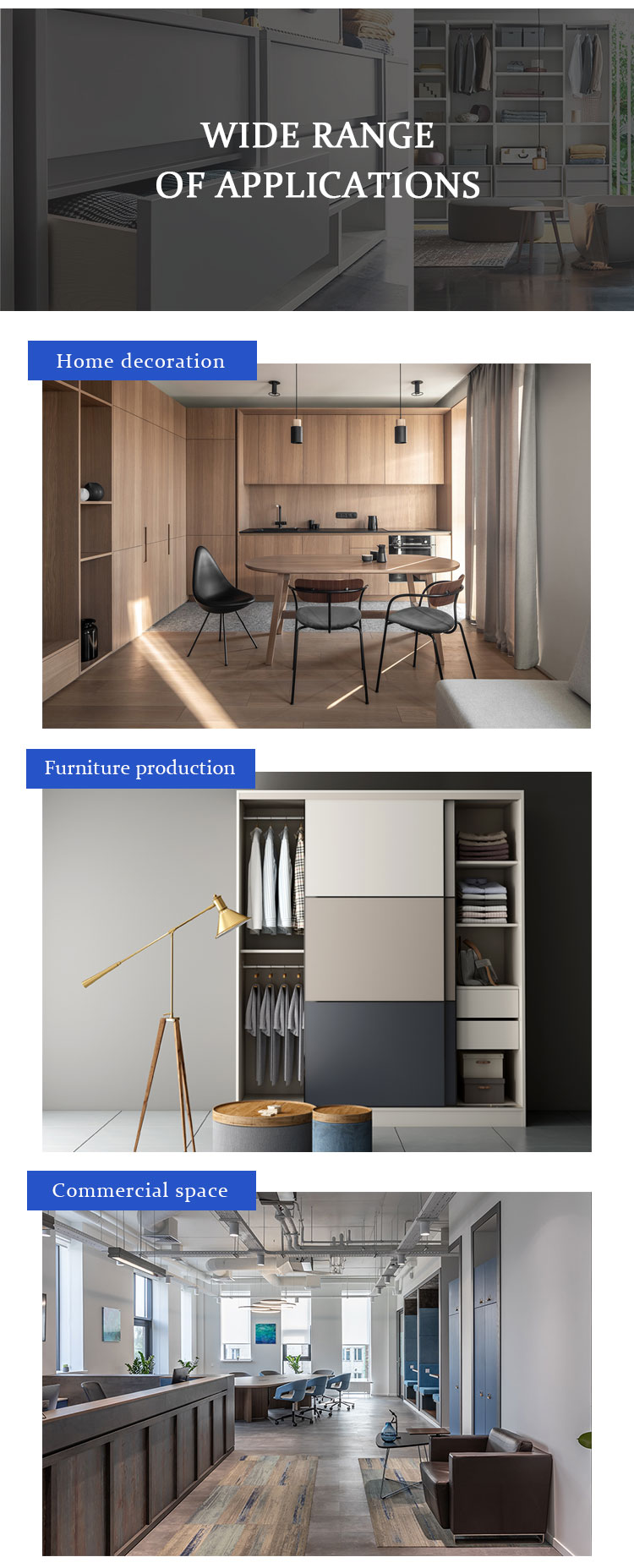

Usage & Performance | Melamine MDF board is widely used for furniture, interior decoration and wood flooring. With good properties, such as, acid & alkali resistant, heat resistant, easy fabric ability, anti-static, easy cleaning, long-lasting and no seasonal effect. | ||

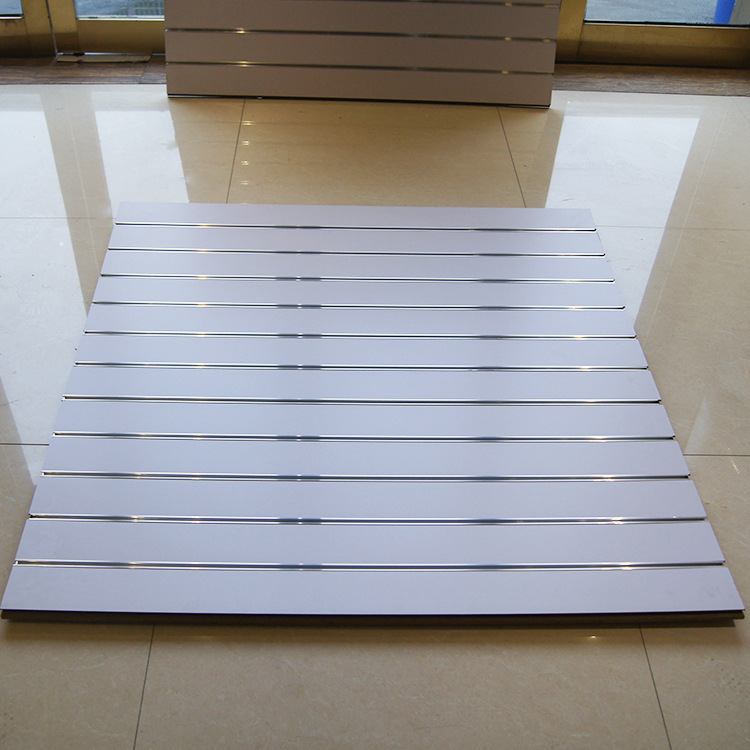

Product Display

Understanding the Different Types of Melamine Faced Panels

Melamine faced panels are highly versatile, durable, and cost-effective, making them a popular choice for a wide range of applications in furniture manufacturing, cabinetry, and interior decor. Depending on the substrate and the type of melamine used, there are several categories of melamine faced panels, each offering unique properties that cater to specific uses. In this article, we’ll delve into the different types of melamine faced panels, their features, and their common applications.

1. Thermal-Fused Melamine (Low-Pressure Melamine)

Thermal-fused melamine, also known as low-pressure melamine, is produced by fusing a melamine-impregnated paper onto a substrate using moderate heat and pressure. The substrate is typically particleboard, medium-density fiberboard (MDF), or plywood.

Features: Low-pressure melamine is known for its affordability, durability, and easy-to-clean surface. It is available in a wide range of colors, patterns, and textures, making it a versatile choice for both residential and commercial applications.

Applications: Often used in ready-to-assemble furniture, store fixtures, and cabinetry, low-pressure melamine panels provide an attractive, durable surface at a budget-friendly price point.

2. Vertical-Grade Melamine Panels

Vertical-grade melamine is a thin and lightweight option, where a melamine-coated decorative paper is applied to a substrate using heat and pressure. The substrate is usually made of particleboard or MDF, resulting in a panel that is resistant to scratches, stains, and impacts.

Features: This grade of melamine is highly resistant to everyday wear and tear, making it ideal for vertical surfaces. It is available in a broad range of solid colors and wood grain patterns.

Applications: Vertical-grade melamine is primarily used for wall panels, partitions, and door surfaces, where a lightweight yet durable material is required. It is particularly popular for office interiors and other vertical applications.

3. Horizontal-Grade Melamine Panels

Horizontal-grade melamine is similar in construction to vertical-grade melamine but is designed to be thicker and more robust. It offers additional durability to withstand the wear and tear of horizontal surfaces, such as countertops and tabletops.

Features: This type of panel is highly resistant to scratches, stains, and heat, making it perfect for surfaces that endure frequent use. It comes in a variety of colors and patterns to suit different design themes.

Applications: Horizontal-grade melamine is commonly used in commercial and institutional settings such as offices, schools, and hospitals, where high durability and ease of maintenance are essential.

4. Standard Melamine Faced Panels

Standard melamine faced panels consist of a substrate like MDF or particleboard that is covered with a decorative melamine paper layer. These panels are available in a broad array of colors, patterns, and textures.

Features: They are valued for their aesthetic versatility and are typically used for furniture and cabinetry. Standard melamine panels are easy to clean and maintain.

Applications: Used in a variety of home and office furniture, including cabinets, wardrobes, and shelves, as well as for decorative wall panels.

5. High-Pressure Laminate (HPL) Melamine Faced Panels

HPL panels are made by bonding multiple layers of kraft paper impregnated with melamine resin under high pressure and temperature. This process results in an extremely durable panel that can withstand heavy usage.

Features: HPL panels are highly resistant to scratches, impact, and general wear, making them ideal for high-traffic areas. Their durability and resistance to chemicals and moisture make them suitable for rigorous environments.

Applications: HPL panels are widely used in commercial and institutional interiors such as schools, hospitals, and office spaces, as well as for countertops, tables, and other furniture that requires a hard-wearing surface.

6. Compact Laminate Melamine Faced Panels

Compact laminate panels are produced using a similar process to HPL, but under even higher pressure and temperature, resulting in a denser and thicker panel.

Features: The enhanced density makes these panels extremely durable, water-resistant, and resistant to chemicals and heat. They are also self-supporting and do not require additional support or backing.

Applications: Ideal for use in wet environments such as bathrooms, locker rooms, and healthcare facilities. These panels are also used for partitions, worktops, and wall cladding in areas that need a highly durable and moisture-resistant material.

7. Fire-Retardant Melamine Faced Panels

Fire-retardant melamine faced panels are treated with special additives during manufacturing to enhance their resistance to fire and smoke. This makes them safer and more suitable for areas where fire safety is a primary concern.

Features: These panels reduce the spread of flames and limit smoke production in case of a fire, providing additional safety features for building interiors.

Applications: Used in public buildings like schools, hospitals, and hotels, as well as in residential applications where enhanced fire safety is desired.

8. Moisture-Resistant Melamine Faced Panels

Moisture-resistant melamine faced panels are treated with moisture-resistant additives during the manufacturing process, enhancing their ability to withstand humid and wet environments.

Features: These panels are specifically designed to resist swelling, warping, or degrading due to exposure to moisture. They are available in various colors and patterns, providing functional and aesthetic value.

Applications: Ideal for use in kitchens, bathrooms, and laundry rooms, where moisture exposure is a concern. They are also used for cabinetry and shelving in humid environments.

Conclusion

Each type of melamine faced panel has unique features that make it suited for specific applications. From standard panels used in cabinetry to high-pressure laminates designed for high-traffic areas, melamine faced panels provide a versatile, durable, and cost-effective solution for various design and functional needs. Understanding the differences between these types can help you choose the right material for your project, ensuring both aesthetic appeal and long-lasting performance. Whether you are planning a residential renovation or outfitting a commercial space, there is a melamine faced panel to meet your requirements.

Use

Packing & Delivery