OSB Board 11MM

Brand YZY

Product origin Linyi

Delivery time 7 Days

Supply capacity 20 Containers/Week

What is OSB ?

OSB is Oriented strand board, is the upgrading of the traditional particleboard products,OSB mechanical properties with directionality, durability, moisture resistance and dimensional stability than ordinary particleboard.With a small expansion coefficient, no distortion, good stability, uniform material and nail holding high performance.

Oriented strand board (OSB), also known as flakeboard, and appetite in British English,is a type of engineered wood similar to particle board, formed by adding adhesives and then compressing layers of wood strands (flakes) in specific orientations.

Product Description

The OSB Board Manufacturing Process: Crafting Durable and Versatile Construction Material

Oriented Strand Board (OSB) has become a staple in the construction industry, thanks to its strength, affordability, and versatility. The manufacturing process behind OSB is a fascinating blend of advanced technology and precise engineering that transforms raw timber into a high-performance building material. Let’s take a closer look at how OSB boards are made, the techniques involved, and the benefits of this engineered wood product.

Step 1: Timber Procurement and Preparation

The OSB manufacturing process begins with the careful selection and procurement of timber supplies. Softwood species, such as pine and aspen, are commonly used due to their availability and structural properties. Once the timber is sourced, it is debarked and shredded into small strands. This initial preparation is crucial, as the quality of the wood strands significantly impacts the final product.

Step 2: Layering the Wood Strands

After shredding, the wood strands are oriented in a cross-layered arrangement. This layering technique enhances the board's strength and stability, mimicking the natural structure of wood. By alternating the orientation of the strands, the resulting OSB panel can better withstand various stresses, making it ideal for load-bearing applications in construction.

Step 3: Application of the Resin Binder

Next, the wood strands are coated with a resin binder, typically a waterproof phenol-formaldehyde adhesive. This resin is essential for bonding the strands together and providing moisture resistance. The choice of resin significantly affects the board's durability and performance, especially in environments where exposure to moisture is a concern.

Step 4: Pressing and Curing

Once coated, the strands are laid out in layers and fed into a continuous press. Here, high temperature and pressure are applied to compress the layers, activating the resin and causing it to cure. This process results in a strong, cohesive panel that retains the structural integrity required for various construction applications. The precision of this step ensures that the OSB board is uniform in quality and possesses consistent structural properties throughout.

Step 5: Cutting and Finishing

After curing, the OSB panels are cooled and then cut to specific dimensions. This flexibility allows manufacturers to customize the board's thickness and size, catering to different construction and renovation needs. The finishing process may also include sanding or treating the surface to enhance its appearance and performance characteristics.

Benefits of OSB Boards

The advanced manufacturing process behind OSB boards contributes to their numerous advantages:

Affordability: OSB is typically more cost-effective than traditional plywood, making it an attractive choice for builders and contractors.

Strength and Durability: The engineered design and high-quality materials result in a product that can handle heavy loads, making it suitable for framing, flooring, and roofing applications.

Consistency: The manufacturing techniques ensure that OSB boards are uniform in quality, providing reliable performance across various projects.

Versatility: Customizable thickness and dimensions mean that OSB can be used in a wide range of applications, from residential construction to industrial projects.

Sustainability: OSB boards are often made from fast-growing, renewable wood sources, and the efficient use of timber resources contributes to environmentally friendly building practices.

Conclusion

The OSB board manufacturing process exemplifies the innovation and precision required to produce a reliable and versatile engineered wood product. By transforming timber into a strong, cost-effective material, OSB has secured its place as a vital component in modern construction. Its unique properties, combined with the advanced techniques used in its production, continue to make OSB an essential choice for builders, architects, and homeowners alike. Whether for framing, flooring, or a myriad of other applications, OSB stands as a testament to the capabilities of modern manufacturing in creating high-performance building materials.

Specification

Type | Flakeboards |

Warranty | 1 Year |

After-sale Service | Online technical support, other |

Project Solution Capability | Others |

Application | Apartment |

Design Style | Modern |

Place of Origin | China |

Brand Name | YZY |

Model Number | 1 |

Usage | Indoor or Outside |

Surface Finishing | UNFINISHED |

Grade | FIRST-CLASS |

Slab Structure | Oriented Strand Boards(OSB) |

Product name | OSB board |

Size | 1220mm*2440mm,1250mm*2500mm |

Thickness | 9~25mm |

Glue | E0/E1/E2/MR |

Core Material | Poplar,Pine,Brich |

Grade | OSB1/2/3/4 |

Density | 600-700kg/m3 |

Payment Term | T/T, L/C at sight |

MOQ | 1*20GP |

Delivery Time | Within 15 Days Receiving Deposit |

Composition and Manufacturing Process: OSB is made from small, thin strands of wood, usually aspen or poplar, which are layered in specific orientations to enhance its structural integrity. These strands are bonded together using wax and adhesive resins, such as isocyanate or phenol formaldehyde. The layers are then compressed under high pressure and heat, resulting in a durable and rigid panel.

Structural Properties: One of the key features of OSB is its structural strength. The orientation of the wood strands in multiple layers provides dimensional stability and resistance to warping or twisting. OSB is available in different thicknesses, and its structural properties make it suitable for various applications, including wall sheathing, flooring, and roofing.

Advantages of OSB:

Cost-Effective: OSB is often more affordable than traditional plywood, making it a cost-effective choice for builders and contractors.

Sustainability: OSB is considered environmentally friendly because it utilizes fast-growing wood species and small-diameter logs that might not be suitable for other applications.

Consistent Quality: The manufacturing process of OSB ensures consistent quality, reducing the likelihood of defects and weaknesses in the material.

Versatility: OSB can be used in a wide range of construction projects, from residential homes to commercial buildings, due to its versatility and adaptability.

Applications of OSB:

Construction: OSB is commonly used as sheathing for walls, roofs, and floors. Its structural strength and dimensional stability make it a reliable choice for supporting the load in various construction applications.

Furniture and Cabinetry: OSB is also utilized in the production of furniture and cabinetry. Its affordability and durability make it an attractive option for manufacturers seeking a balance between cost and quality.

DIY Projects: Homeowners and DIY enthusiasts often choose OSB for various projects, such as shelving, decking, and other structural elements, thanks to its ease of use and cost efficiency.

Conclusion: Oriented Strand Board (OSB) has become a staple in the construction industry, offering a cost-effective and reliable alternative to traditional plywood. Its unique composition, structural properties, and versatility make it a preferred choice for a wide range of applications. As the demand for sustainable and affordable building materials continues to grow, OSB is likely to maintain its prominent role in the ever-evolving field of construction and design.

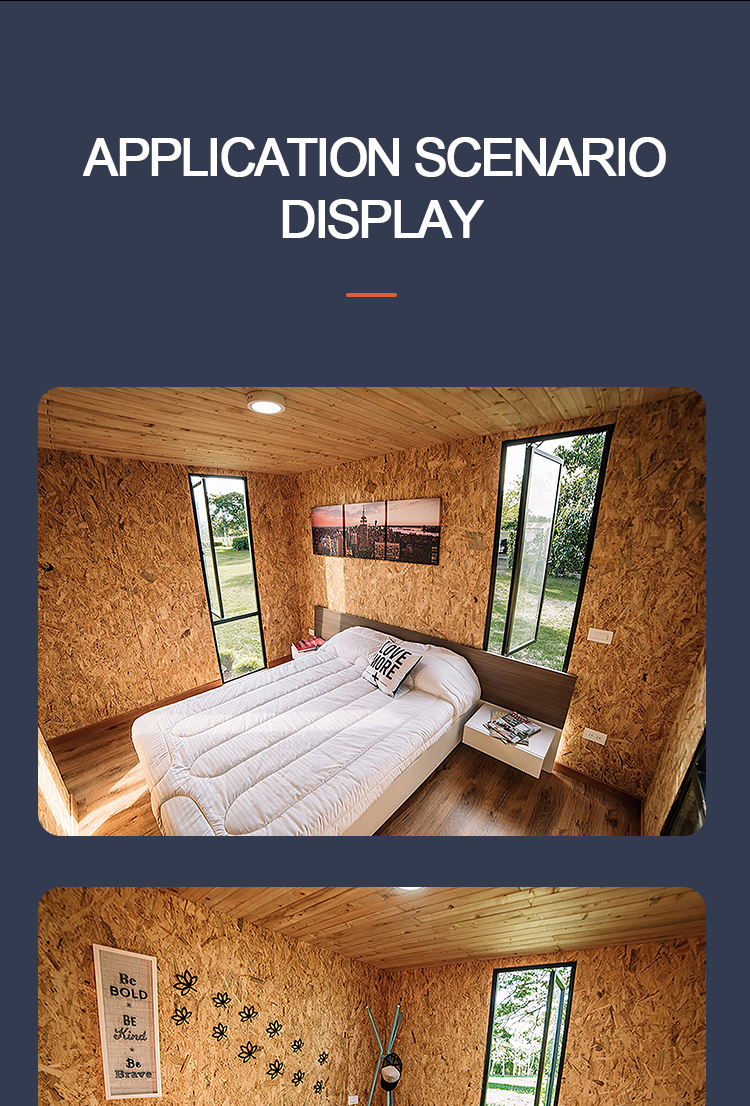

Application

Packing & Delivery

Linyi YZY Interantional Trade Co,.Ltd,

Adress:Room 2204 Dongfang Jiayuan Building , Lanshan District,Linyi City Shandong Province,China 27600

Construciton Plywood Supplier |www.sowowood.com |

Skype:yzy@yzylinyi.com |Wechat:17753974353|What'sApp/Viber:+86 15094723345