Understanding Film-Faced Plywood

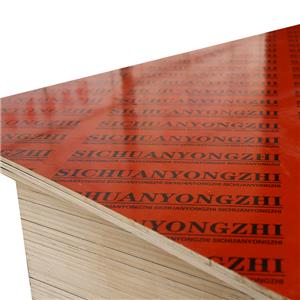

Composition:Film-faced plywood is typically crafted from high-grade wood veneers, bonded together with a waterproof adhesive. What sets it apart is the outer layer—a film made of phenolic resin. This synthetic resin not only enhances the plywood's water resistance but also shields it from chemicals and abrasions. This protective film is what makes film-faced plywood well-suited for the demanding environment of concrete formwork.

Characteristics:The defining feature of film-faced plywood is its durability and resistance to external elements. The phenolic film on the surface creates a smooth, impervious layer that prevents concrete from adhering to the plywood. This facilitates easy removal of the formwork and allows for its reuse, making it a cost-effective solution for construction projects. Additionally, the film imparts waterproof qualities to the plywood, ensuring it remains structurally sound even in the presence of moisture.

Applications:Film-faced plywood finds its primary application in the construction industry, where it is extensively used for creating formwork for concrete structures. Walls, columns, beams, and slabs are just a few examples of the elements that can be efficiently formed using film-faced plywood. The smooth surface of the plywood ensures a high-quality finish on the concrete, reducing the need for additional finishing work. Beyond construction, film-faced plywood is also employed in the transportation industry for truck floors and containers, highlighting its versatility.

Advantages:The use of film-faced plywood in construction projects offers several notable advantages. Firstly, it provides a cost-effective solution due to its reusability. The ability to use the same formwork multiple times significantly reduces the overall project costs by minimizing the need for new materials. Moreover, the smooth surface minimizes imperfections in the concrete, contributing to a more aesthetically pleasing final product. The waterproof nature of film-faced plywood adds durability, making it suitable for both indoor and outdoor applications.

Conclusion:In conclusion, understanding film-faced plywood involves recognizing its unique composition, characteristics, applications, and the advantages it brings to construction projects. This specialized plywood has become an indispensable tool in the construction industry, offering durability, cost-effectiveness, and versatility. As construction practices evolve, film-faced plywood continues to prove its worth as an essential component in the creation of resilient and aesthetically pleasing concrete structures.