Red Film Building Construction Plywood

Brand YZY

Product origin China

Delivery time Within 15 days after received the deposit

Supply capacity 2500 Pieces/Day

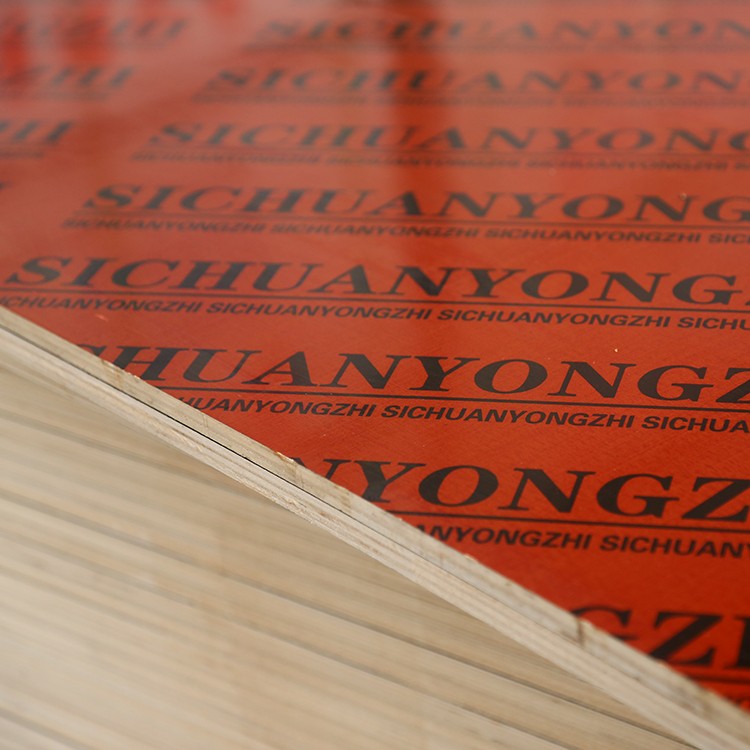

Film Faced Plywood

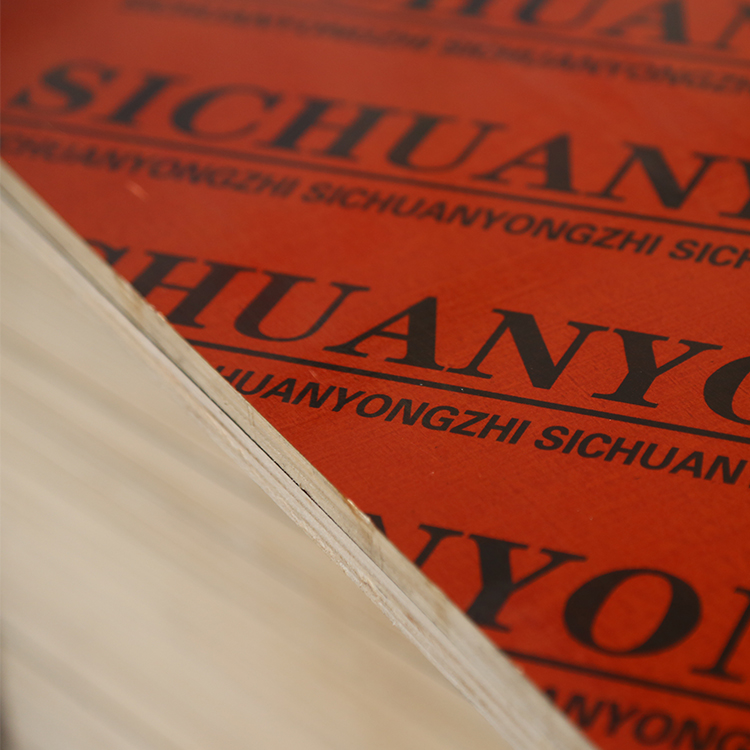

(1)membrane paper surface can be printed exclusive text and logo.

(2)widely used in construction, decoration, furniture and packaging.

Anti Slip Plywood

(1)ONon-Skid Pattern: eggcrate, hexagon, rhombus, gridding etc.

(2)Widely used in construction, stage, container and car floor.

Product Description

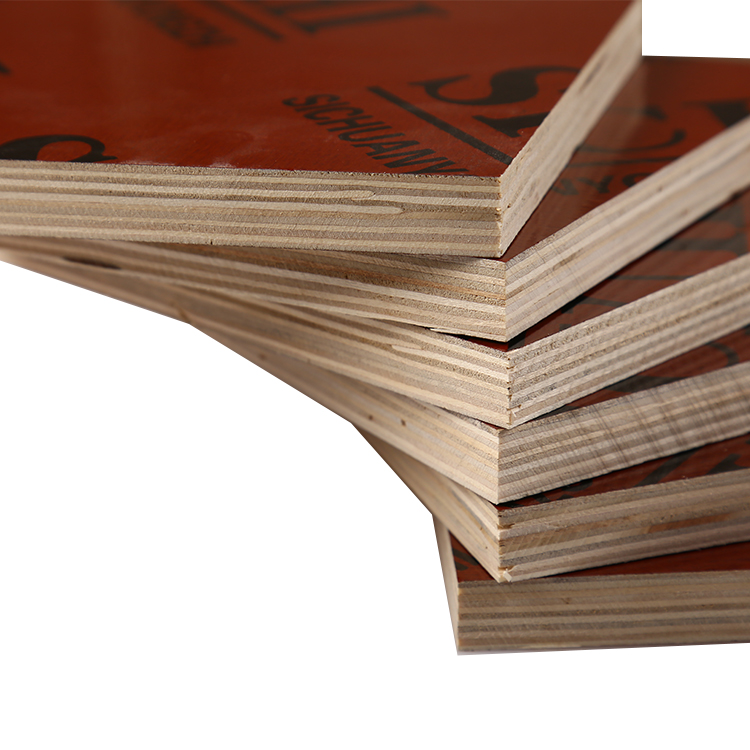

Product Name | Film Faced Plywood |

Size | 1220*2440mm/915*1830mm/1500*3600mm as your need |

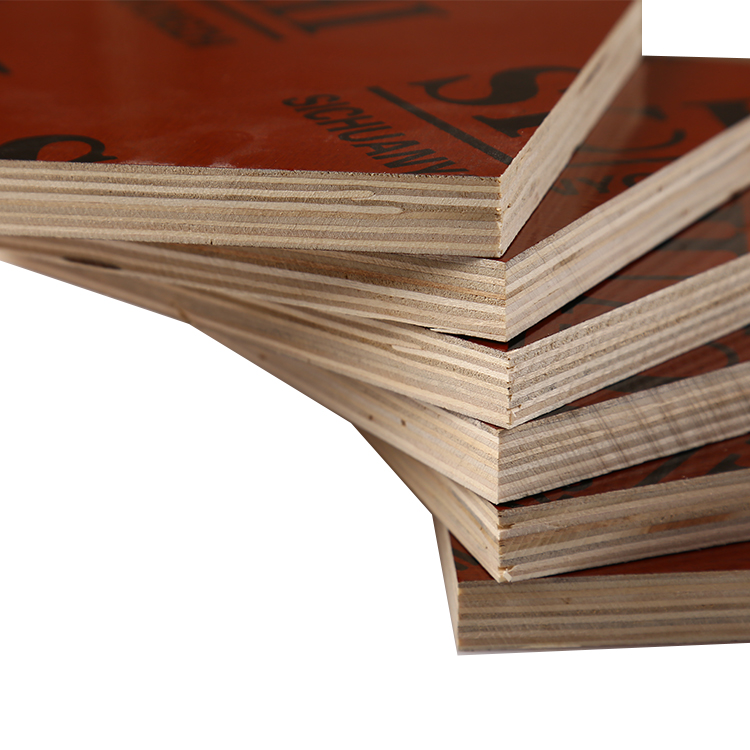

Product Thickness | 9mm/12mm/15mm/18mm etc |

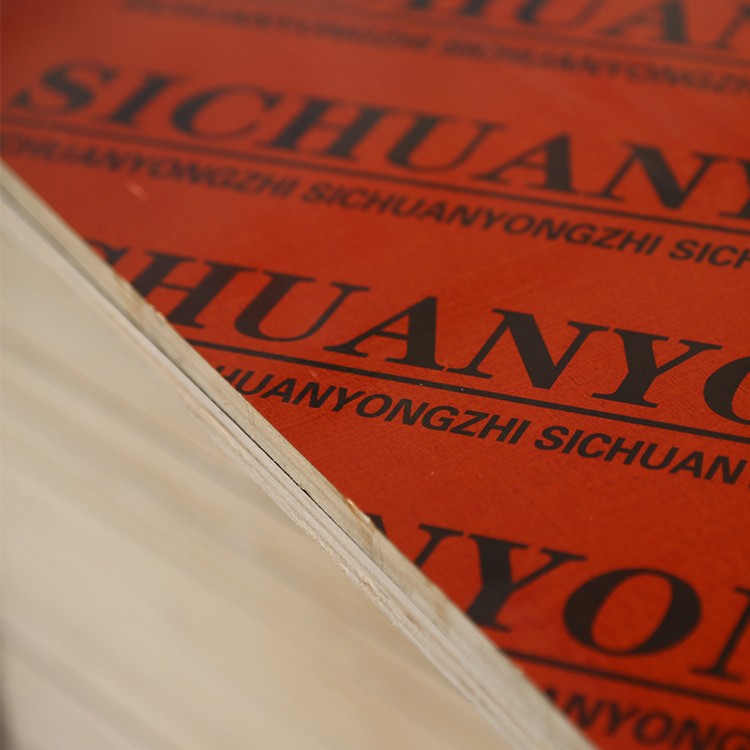

Core | 100% Poplar or combi |

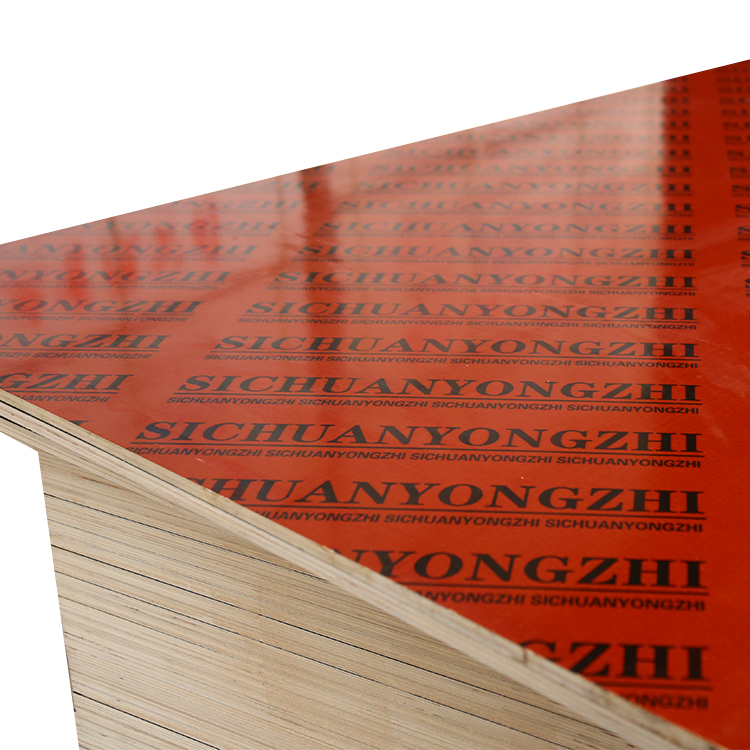

Option | Black Film and Brown Film or Red Film |

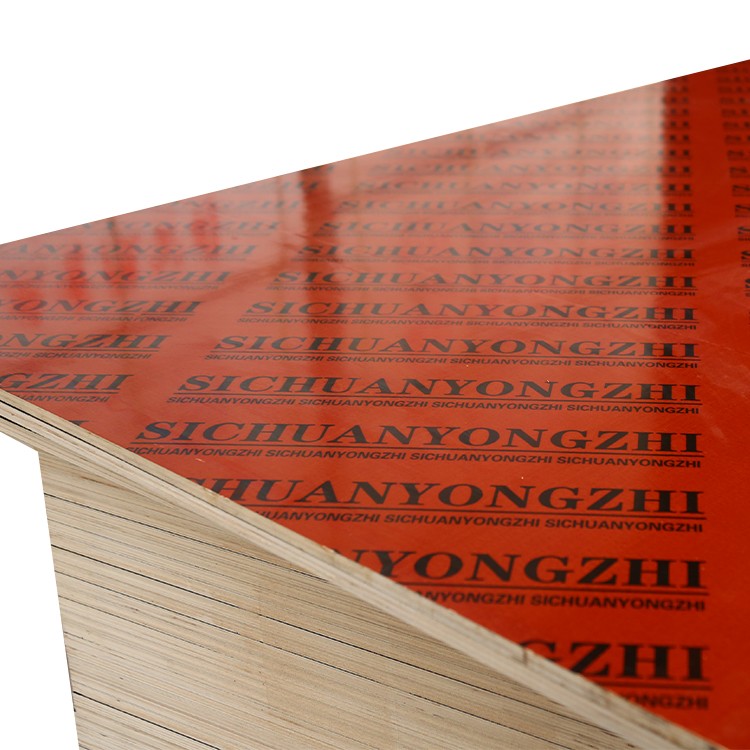

Edge | Sealed with water proof paint, paint color can be upon request |

Glue | Melamine or WBP |

Hot Press Time | 1 time for whole panel 2 times for core and 1 time for film |

Formaldehyde Emission level | Carb,E0,E1,E2 |

Usage | Real estate construction /formwork panel/Building |

Package | pallets are covered with plywood or carton boxes and strong steel belts |

Payment Term | 30% deposit TT, L/C at sight. |

Delivery Time | Within 15 days after received the deposit |

Supply Ability | 2500 Pieces/Day |

(1)Widely used in construction, stage, container and car floor.

(2)Widely used in all kinds of buildings, can be used more than 30 times.

Finger Joint Core Plywood

(1)The price is very cheap.

(2)It's very suitable for rainless country

Product Display

Understanding Film Faced Plywood: A Durable Solution for Construction Needs

Film faced plywood has become a preferred choice in the construction industry due to its exceptional durability and resistance to environmental factors. Covered with resin-treated paper that transforms into a protective film during production, this type of plywood is specifically designed for applications requiring strength and resilience. Let’s delve into what makes film faced plywood a vital material for various construction projects.

What is Film Faced Plywood?

Film faced plywood consists of layers of wood veneer that are glued together and then coated with a resin-impregnated paper. This coating not only creates a smooth, protective surface but also enhances the plywood's resistance to water, chemicals, fungi, and mold. As a result, film faced plywood is particularly well-suited for formwork and shuttering applications, where exposure to moisture and heavy wear is common.

Benefits of Film Faced Plywood

Water Resistance: The resin-treated surface provides excellent water resistance, making it ideal for outdoor projects and in environments where moisture is a concern. This characteristic also ensures that the plywood maintains its integrity over time, reducing the risk of warping or swelling.

Durability: Film faced plywood is designed to withstand wear and tear, making it a reliable choice for construction sites. Its robust surface resists scratches and abrasions, ensuring that the panels remain in good condition throughout their use.

Ease of Use: This type of plywood is easy to cut and clean, facilitating efficient handling and installation. Its manageable weight and structural integrity allow for quick assembly and disassembly, saving time on construction projects.

Cost-Effectiveness: By reducing the need for additional protective coatings and treatments, film faced plywood can lower overall construction costs. Its durability means fewer replacements and repairs, providing long-term savings.

Types of Film Faced Plywood

We offer two primary types of film faced plywood to cater to diverse project requirements:

Birch Film Faced Plywood: Known for its exceptional quality, birch film faced plywood is highly resistant to water and easy to work with. It is recognized as one of the finest types of plywood available, making it an excellent choice for high-end construction applications where performance and aesthetics matter.

Poplar Film Faced Plywood: Lighter and softer than birch, poplar film faced plywood is also easy to clean and cut. It is a versatile option suitable for a range of applications, particularly where weight considerations are essential. Its affordability and performance make it a popular choice for various construction needs, including shuttering and formwork.

Conclusion

Film faced plywood stands out as a durable, cost-effective solution for a wide range of construction applications. Its superior water resistance, durability, and ease of handling make it a go-to material for builders and contractors. With options like birch and poplar film faced plywood available, you can select the ideal product that meets your project specifications while ensuring high-quality results. Whether for indoor or outdoor use, film faced plywood is a reliable choice that enhances both functionality and performance in construction projects.

Packing & Delivery

Linyi YZY Interantional Trade Co,.Ltd,

Adress:Room 2204 Dongfang Jiayuan Building , Lanshan District,Linyi City Shandong Province,China 27600

Construciton Plywood Supplier |www.sowowood.com |

Skype:yzy@yzylinyi.com |Wechat:17753974353|What'sApp/Viber:+86 15094723345