OSB Plywood for Decration

wholesale Linyi Supply 9mm 12mm 15mm 18mm osb3 Waterproof OSB

Product name | OSB3 Waterproof |

Material | Poplar, Pine, Combi, |

Size | 1220x2440,1250x2500 or as per your requirements |

Thickness | 8-10mm>10-18mm>18-25mm or as your request. |

Tolerance | Length &Width:+/-2mm

Thickness:+/ -0.2mm |

Glue | WBP, Melamine, MR,E1,E2 |

Application | OSB3 construction gared,OSB2 packing gared |

Density | 650-680KG/CBM |

Package | Standard export package with pallet or in bulk according to your request |

Usage | Roof decking, furniture, packing, hoarding, signboards and portable building, constructional insulation board, |

Payment | T/T or L/C at sight |

Delivery | Within 15-20 days after getting your deposit or L/C |

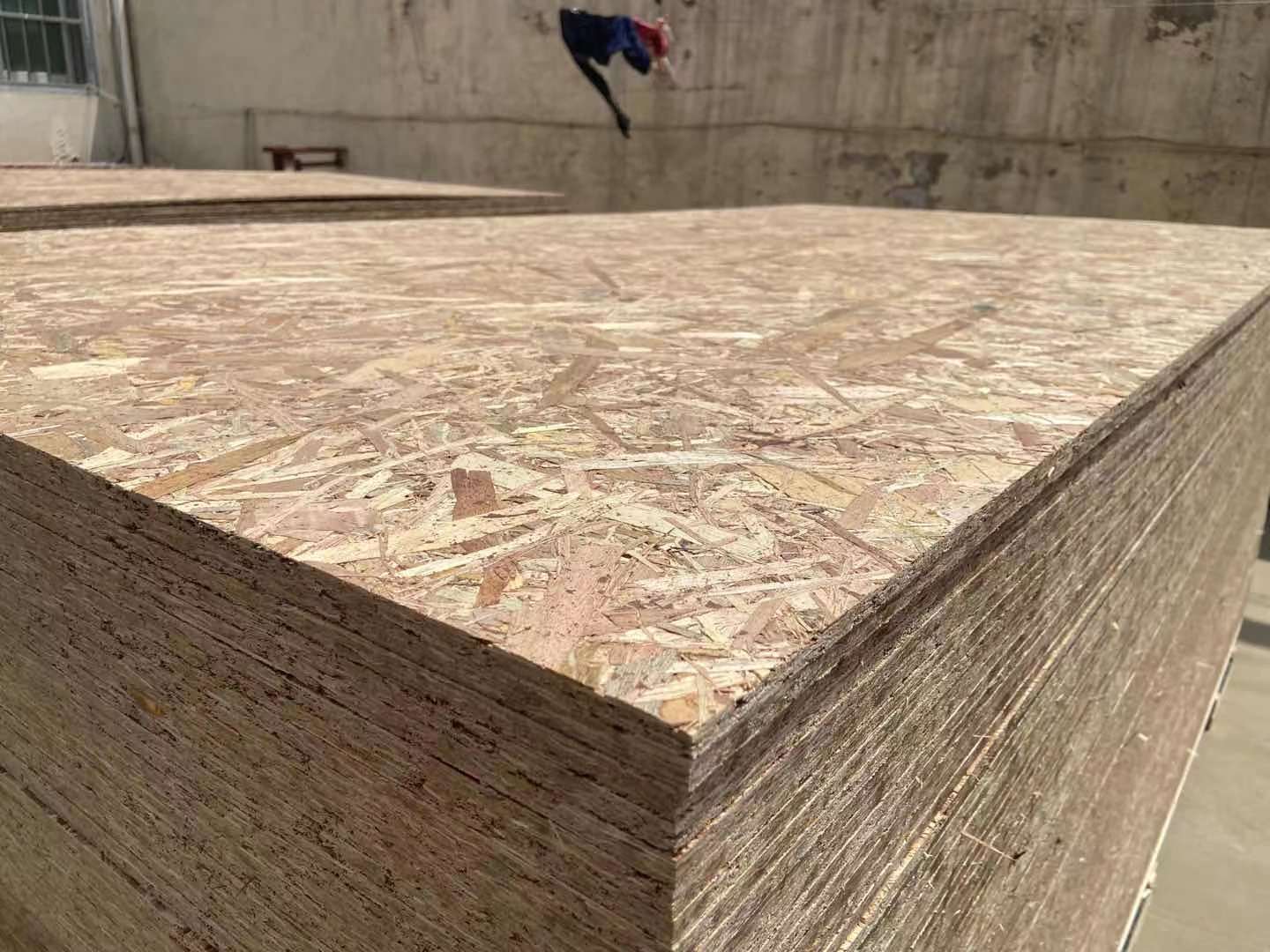

Details Images

Oriented Strand Board (OSB) is an engineered wood product renowned for its strength, durability, and cost-effectiveness. It has emerged as a fundamental material in modern construction, utilized extensively in both residential and commercial building projects. OSB is crafted by compressing and gluing layers of wood strands in specific, cross-directional orientations, which imparts enhanced mechanical properties to the board, making it structurally sound and dimensionally consistent.

The manufacturing process of OSB starts with slicing fast-growing tree species into long, slender wood strands. These strands are then coated with wax and synthetic resin adhesives before being arranged in cross-directional layers. Following this, the layers are compressed under high heat and pressure, resulting in a rigid panel that boasts high resistance to moisture, bending, and warping. The cross-layering technique significantly boosts the board's strength, ensuring uniformity and allowing OSB to perform comparably to, if not better than, traditional plywood.

One of the primary advantages of OSB over traditional plywood is its cost-efficiency. OSB generally costs less to produce, providing an economical alternative without compromising structural integrity. Its ability to be manufactured in larger panels with fewer joints enhances performance in construction applications that require seamless continuity, such as wall sheathing, subflooring, and roof decking.

Moreover, OSB's environmental sustainability distinguishes it from other materials. The production involves using smaller, fast-growing tree species like aspen, poplar, or southern yellow pine, which reduces dependency on large, old-growth timber. This efficient use of resources, where nearly every part of the harvested tree is utilized, minimizes waste and promotes eco-friendly building practices.

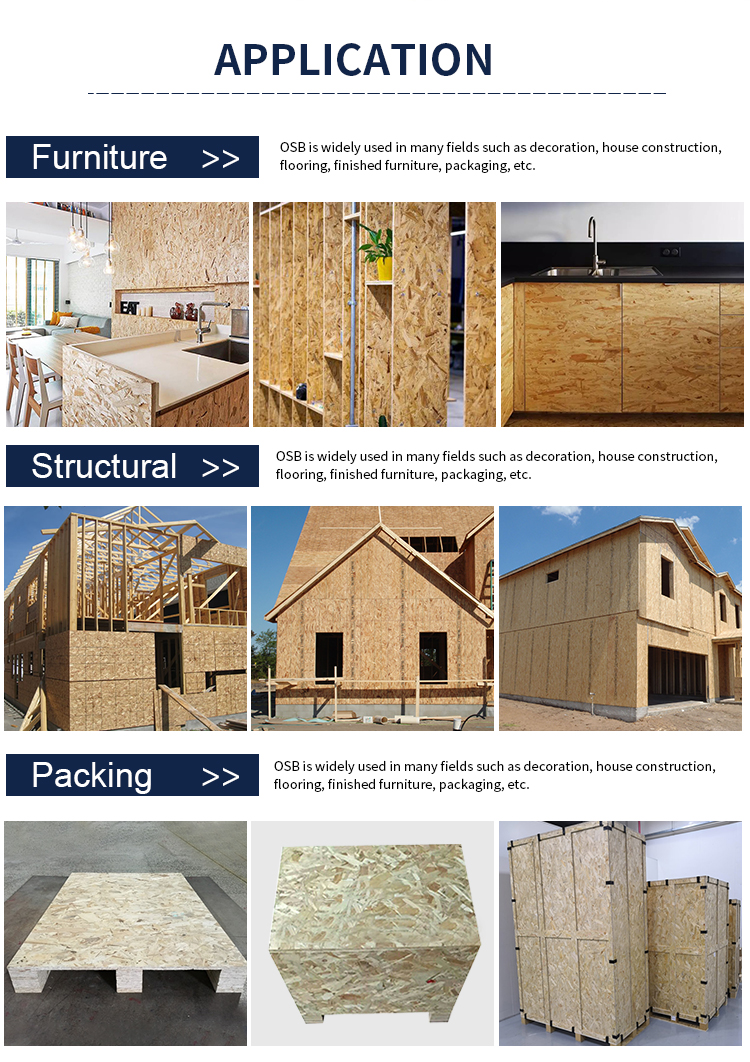

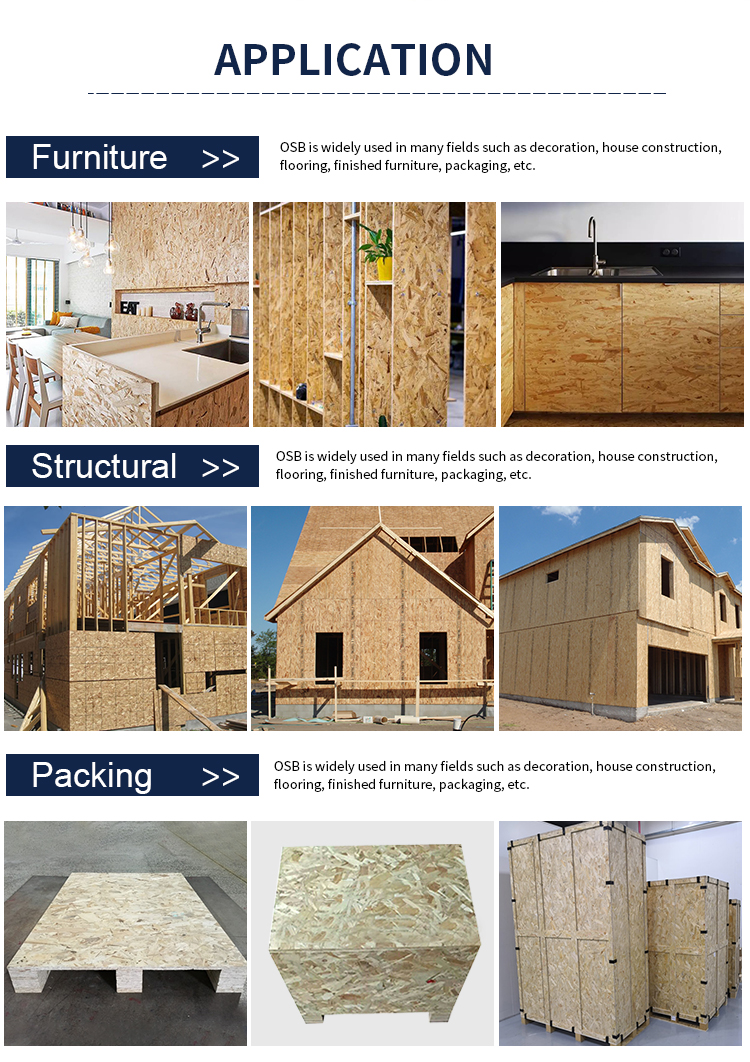

The versatility of OSB makes it an indispensable choice for a plethora of construction purposes:

Wall Sheathing: OSB panels provide lateral stability to framed structures, helping them withstand wind forces and seismic activity.

Roof Decking: OSB's strength makes it an ideal underlayment for roofing materials like shingles or tiles, effectively managing loads.

Subflooring: Its durability and strength ensure it can support heavy loads in living spaces, making it an excellent subflooring material when span ratings are considered.

Furniture and Packaging: The low cost and solid performance of OSB extend its use beyond structural applications to furniture manufacturing and packaging solutions.

While OSB is highly durable and reliable, it is essential to consider its moisture sensitivity. Although modern manufacturing advancements have enhanced its water resistance, prolonged exposure to moisture can lead to swelling or degradation in untreated boards. For outdoor or moisture-prone applications, builders should opt for moisture-resistant OSB variants or ensure proper sealing during installation.

OSB board stands out as an efficient, cost-effective, and highly versatile building material. Its engineered composition ensures strength, durability, and uniformity, presenting a dependable alternative to traditional plywood for most construction needs. With the increasing demand for sustainable and affordable materials, OSB continues to gain popularity among builders and contractors. Whether for residential homes or large commercial projects, OSB provides the durability and flexibility required to meet modern building standards.

At YZY, we are dedicated to providing top-quality OSB boards tailored to meet your construction needs. As a premier manufacturer from China, we bring you a comprehensive range of products, including MDF, Film Faced Plywood, Birch Plywood, Particle Board, and more. Trust YZY for reliable, eco-friendly building solutions.

OSB/2 – Load-bearing boards for use in dry conditions

OSB/3 – Load-bearing boards for use in humid conditions

OSB/4 – Heavy-duty load-bearing boards for use in humid conditions

Who are we?

We are based in Shangdong, China, start from 2016,sell to Western Europe(80.00%),North America(10.00%),Africa(10.00%). There are total about 11-50 people in our office.

...more