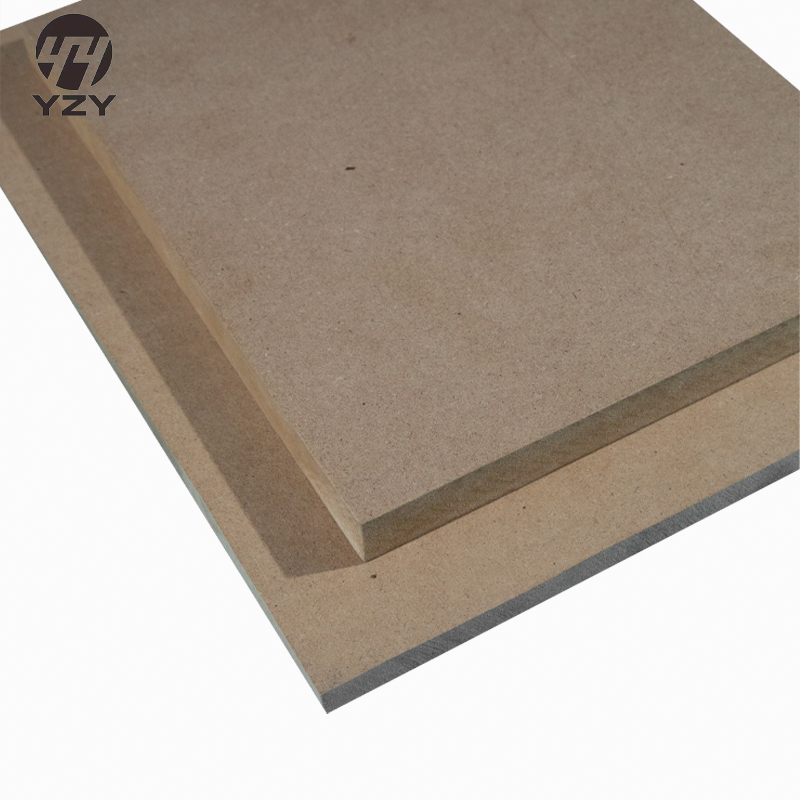

What is MDF

Composition of MDF:

MDF is composed of wood fibers, wax, and resin. The wood fibers are derived from hardwood and softwood sources, which are broken down into small fibers through a mechanical refining process. These fibers are then combined with wax and resin, typically a formaldehyde-based adhesive, to create a homogeneous mixture.

Manufacturing Process:

The manufacturing process of MDF involves several steps. First, the wood fibers are extracted from raw timber using heat and steam. These fibers are then blended with the resin and wax mixture. The resulting homogenized slurry is formed into panels using heat and pressure. The panels are then cooled, cut to size, and sanded to achieve a smooth finish.

Applications of MDF:

MDF's versatility makes it suitable for a wide range of applications. It is commonly used in the furniture industry for manufacturing cabinets, shelves, and other furniture components. Its smooth surface and uniform density also make it a preferred material for painting and finishing. In construction, MDF is employed for interior trim, doors, and panels. Additionally, it serves as a popular material in crafting, providing a stable base for various projects.

Advantages of MDF:

Consistent Quality: MDF offers uniform density and a smooth surface, ensuring consistent quality in finished products.

Versatility: Its composition allows for intricate shaping and detailing, making it adaptable to diverse applications.

Affordability: Compared to solid wood, MDF is often more cost-effective, making it an attractive option for budget-conscious projects.

Paintability: MDF readily accepts paints and finishes, providing designers and craftsmen with a blank canvas for customization.

Disadvantages of MDF:

Susceptibility to Moisture: MDF is prone to swelling and warping when exposed to moisture, limiting its use in high-humidity environments.

Formaldehyde Emissions: The adhesives used in MDF may release formaldehyde, a potential concern for indoor air quality. However, efforts have been made to produce low-formaldehyde or formaldehyde-free MDF.

Not Suitable for Structural Use: While MDF is sturdy, it is not designed for structural applications, and its load-bearing capacity is lower compared to some other materials.

Environmental Considerations:

The environmental impact of MDF production includes the use of wood resources and the emissions associated with the manufacturing process. However, many manufacturers are working towards sustainable practices, such as using recycled wood fibers and eco-friendly adhesives, to mitigate these concerns.

In conclusion, Medium Density Fiberboard is a widely used and versatile material with both advantages and disadvantages. Its popularity is attributed to its cost-effectiveness, uniformity, and adaptability. However, users must carefully consider its limitations, particularly in environments where moisture resistance and formaldehyde emissions are critical factors. As technology advances, the industry continues to explore more sustainable and environmentally friendly options to enhance the overall profile of MDF.