11mm OSB3 And Furniture OSB

Brand YZY

Product origin Linyi City

Delivery time 1week

Supply capacity 1000CBM/Week

What is OSB ?

OSB is Oriented strand board, is the upgrading of the traditional particleboard products,its mechanical properties with directionality, durability, moisture resistance and dimensional stability than ordinary particleboard.

With a small expansion coefficient, no distortion, good stability, uniform material and nail holding high performance.

Oriented strand board (OSB), also known as flakeboard, sterling board and aspenite in British English,is a type of engineered wood similar to particle board, formed by adding adhesives and then compressing layers of wood strands (flakes) in specific orientations. It was invented by Armin Elmendorf in California in 1963.

Product Description

Oriented particle boards (OSB / OSB), type: OSB-2, OSB-3, unpolished, emission class E1, size 2,500 mm x 1,250 mm, 2,440 mm x 1,220 mm, thickness from 6 mm to 22 mm.

OSB/2 – Load-bearing boards for use in dry conditions

OSB/3 – Load-bearing boards for use in humid conditions

OSB/4 – Heavy-duty load-bearing boards for use in humid conditions

Detailed Images

| Product | Oriented strand board (OSB) |

| Material | Poplar, Pine, Combi, Hardwood |

| Glue | WBP / Phenolic /E0 /E1/E2 |

| Size | 1220x2440,1250x2500 or accept customization |

| Thickness | 8-25mm(9mm,11mm,12mm,15mm,18mm) or accept customization |

| MOQ | 40CBM |

| Delivery Time | 15-25 Days |

| Thickness Tolerance | Thickness:+/ -0.2mm |

| Size Tolerance | Length &Width:+/-2mm |

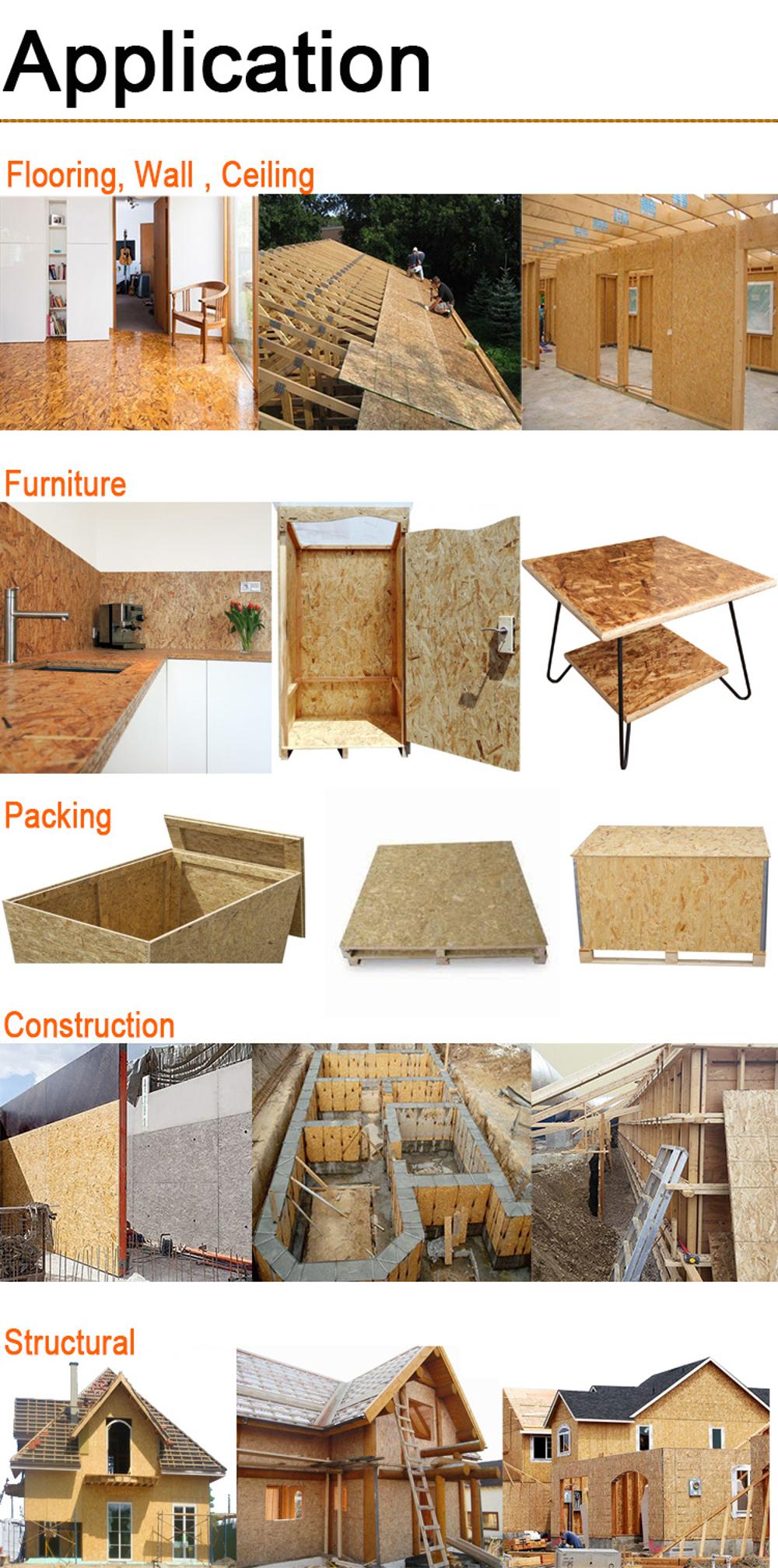

| Usage | Roof decking, furniture, packing, hoarding, signboards and portable building, constructional insulation board, |

| Density | 600-700KG/CBM |

| Production Advantages: | 1) Tight construction and high strength; 2) Minimum twisting, delamination or warping; 3) Water proof, consistent when exposed in the natural or wet environment; 4) Low formaldehyde emission; 5) Good nailing strength, easy to be sawn, nailed, drilled, grooved, planed, filed or polished; 7) Good heat and sound resistant, easy to be coated; 8) Note the OSB 3 is for use on flat roof situtaions, a far better product than standard chipboard or particleboard. |

| Payment | T/T or L/C at sight |

OSB Board Composition: A Foundation of Strength and Sustainability

The composition of Oriented Strand Board (OSB) plays a crucial role in its performance, making it a preferred choice for builders and contractors in a wide array of construction applications. OSB is made by compressing and gluing layers of wood strands in specific orientations, creating a structurally sound material that offers remarkable stability and uniformity.

Key Components of OSB Board

Wood Strands: OSB is composed of long, thin wood strands sliced from fast-growing tree species such as aspen, poplar, and pine. These wood strands are strategically aligned in cross-directional layers to enhance the board's strength and structural integrity.

Adhesive and Wax: The wood strands are bonded together using a combination of waterproof synthetic resins and wax. These adhesives not only ensure that the strands stay tightly bound but also provide a level of moisture resistance, making OSB suitable for various construction environments.

Cross-Layering Process: The layering process is essential to the performance of OSB. By placing the wood strands in alternating, cross-directional patterns, OSB gains enhanced mechanical strength. This process ensures uniform load distribution, allowing the board to handle significant pressure without warping or breaking.

The Importance of OSB's Composition

Strength and Durability: The way OSB is manufactured—compressing layers of wood strands—creates a material that can withstand heavy loads and pressures. This makes it ideal for structural applications such as wall sheathing, roof decking, and subflooring, where strength and stability are critical. The cross-layering adds to the board's overall rigidity, minimizing the risk of bending, cracking, or sagging over time.

Sustainability: OSB is an eco-friendly building material, primarily because it utilizes smaller, fast-growing trees and maximizes the use of wood fibers. By efficiently using nearly every part of the tree, OSB manufacturing reduces waste and supports sustainable forest management practices. Its engineered nature also means it requires less energy to produce than traditional solid wood panels.

Versatility: The consistent, engineered composition of OSB makes it incredibly versatile, allowing it to be used in a variety of construction settings. Whether for exterior sheathing, interior walls, or roofing, OSB provides reliable performance in each application. Its adaptability also extends to non-structural uses, such as furniture and packaging, demonstrating the board’s flexibility in both creative and practical ways.

Reliability and Uniformity: The manufacturing process ensures that OSB boards are dimensionally uniform, providing consistent thickness, density, and strength across each panel. This reliability offers peace of mind for builders, knowing that the materials they use will perform predictably and maintain their integrity throughout the life of the building.

Conclusion

The composition of OSB board is the foundation of its success as a construction material. With its combination of wood strands, strong adhesives, and cross-layering techniques, OSB provides the strength, sustainability, and versatility needed for modern construction projects. Builders and contractors can rely on its consistent performance, durability, and eco-friendly characteristics, making OSB a go-to option for projects requiring robust and reliable wood panels.

Packing & Delivery