DIY laser plywood sheets

Brand YZY

Product origin CHINA

Delivery time 10 days

Supply capacity 10000 CBM/MONTH

1.Quality: smooth surface, easy to cut, drill, laser engrave, draw, paint, stick and more.Manufactured using the latest methods in wood production, plywood panels is extremely strong and durable. The birch board is flat and smooth without warping, the edges hardly need to be sanded, they are neat and smooth, without jagged.

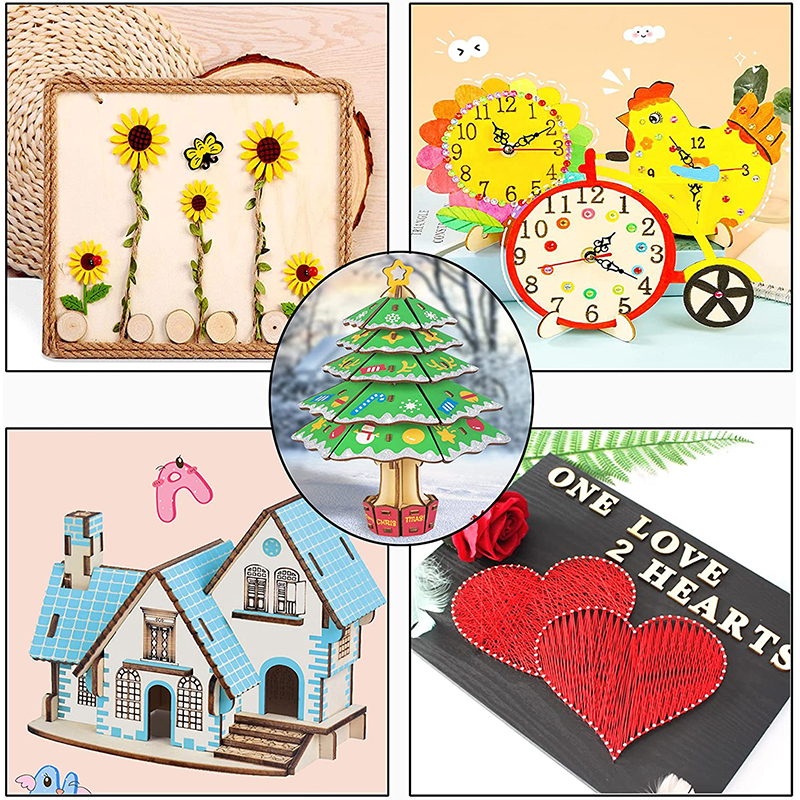

2.DIY Craft Project: specialist plywood is very suitable for home carpenters and woodwork artisans make wooden crafts, such as Easter and Christmas ornaments, holiday decorations, wedding decorations, wood home decor, outdoor welcome signs, name puzzles and small jewelry box etc.

Product Description

| Name | DIY laser plywood sheets | |

| Brand | YZY | |

| Size | 920*920mm, 1220*2440mm or upon request | |

| Thickness Tolerance | 1.5-12mm or upon request | ±0.2mm |

| Core | Poplar, Birch, Basswood | |

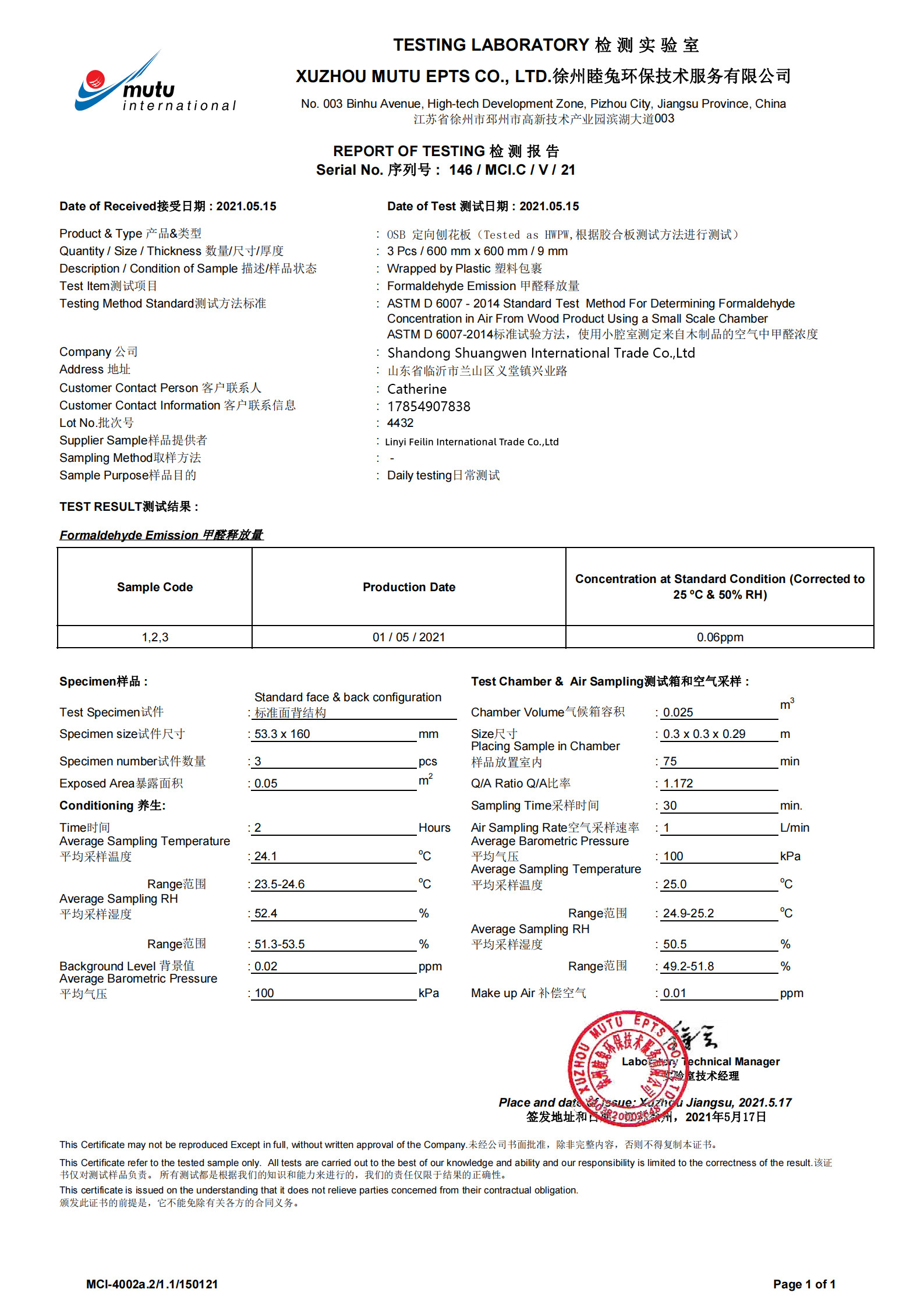

| Glue | E0 | |

| Package | Outer packing: pallets are covered with plywood or carton boxes and strong steel belts | |

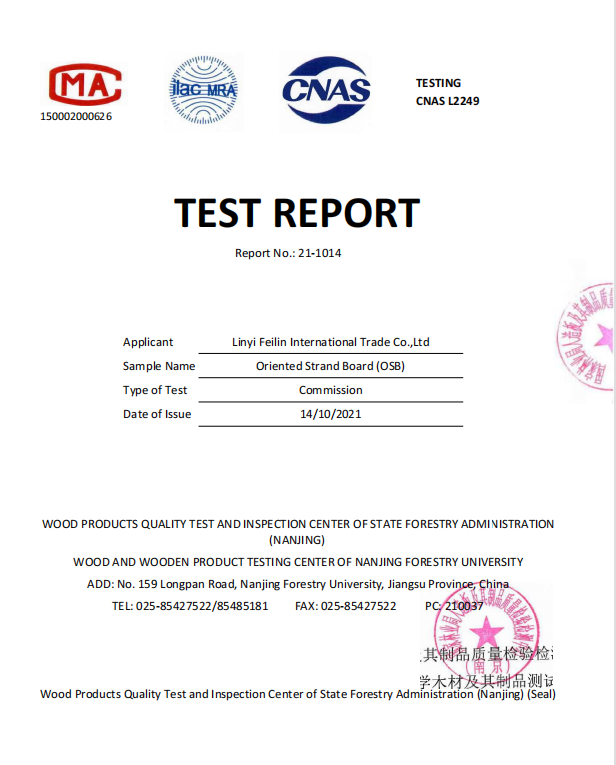

| Certification | CE, ISO,FSC Certified,CARB | |

| Delivery time | Within 2-3 weeks upon down payment or upon opening of L/C | |

| PAYMENT TERM | TT or L/C | |

| Supply ability | 10000 M3/per month | |

| MARK: | Depend customer | |

In the realm of do-it-yourself (DIY) projects, laser plywood sheets have emerged as a transformative medium, offering enthusiasts and creators a unique combination of precision, durability, and versatility. These sheets, crafted from layers of wood veneer bonded together, have become a popular choice for a myriad of projects due to their compatibility with laser cutting technology.

Precision in Design:

The key allure of DIY laser plywood sheets lies in their compatibility with laser cutting machines. This technology allows for intricate and precise designs, making it possible to create detailed patterns, intricate shapes, and fine details with unprecedented accuracy. Whether you are crafting personalized home décor, intricate jewelry, or intricate model structures, the precision afforded by laser cutting on plywood sheets opens up a world of creative possibilities.

Versatility in Applications:

DIY laser plywood sheets are remarkably versatile, finding applications across a broad spectrum of projects. From crafting bespoke signage and personalized gifts to constructing architectural models and intricate wooden puzzles, the versatility of these sheets knows no bounds. The ability to cut through various thicknesses of plywood enables creators to tailor their projects to specific needs, whether it's a delicate ornament or a robust structural component.

Ease of Customization:

One of the standout features of DIY laser plywood sheets is the ease with which they can be customized. With a wide range of plywood thicknesses available, creators can choose the most suitable option for their project. Additionally, the natural finish of the wood allows for further customization through staining, painting, or varnishing, providing a canvas for personal expression. The DIY community values this adaptability, as it enables the realization of unique and individualized creations.

Durability and Sustainability:

Beyond their creative potential, DIY laser plywood sheets offer a durable and sustainable material choice. Plywood, inherently strong due to its layered construction, ensures that finished projects exhibit stability and longevity. Additionally, plywood is a sustainable choice compared to solid wood, as it maximizes the use of available wood resources through its layered composition.

Project Inspiration:

The range of projects achievable with DIY laser plywood sheets is vast. For home decor enthusiasts, these sheets can be transformed into intricate lampshades, wall art, or personalized wooden signs. Model makers can craft detailed architectural models, miniature furniture, or even replicate historical artifacts with remarkable accuracy. The possibilities extend to the realm of fashion, with creators designing laser-cut wooden accessories such as earrings, necklaces, and watches.

DIY Laser Cutting Process:

While the creative possibilities are exciting, it's essential to understand the DIY laser cutting process. Creators typically begin by designing their projects using graphic design software. Once the design is finalized, the laser cutting machine precisely follows the specified pattern, cutting through the plywood sheets with accuracy. This process requires careful consideration of settings such as power, speed, and frequency to achieve the desired results.

Conclusion:

DIY laser plywood sheets have undoubtedly revolutionized the world of creative expression, offering enthusiasts the tools to turn their imaginative concepts into tangible, finely detailed realities. The precision, versatility, and sustainability of these sheets make them an invaluable asset in the hands of DIY aficionados, unlocking a realm of possibilities for innovative and personalized projects. As technology continues to advance and the DIY community thrives, the role of DIY laser plywood sheets is poised to grow, inspiring a new wave of creators to push the boundaries of their imagination.

Packaging & Shipping

Linyi Sowo Interantional Trade Co,.Ltd,

Adress:Room 2204 Dongfang Jiayuan Building , Lanshan District,Linyi City Shandong Province,China 27600

Construciton Plywood Supplier |www.sowowood.com |

Skype:yzy@yzylinyi.com |Wechat:17753974353|What'sApp/Viber:+86 15094723345

We are based in Shangdong, China, start from 2016,sell to Western Europe(80.00%),North America(10.00%),Africa(10.00%). There are total about 11-50 people in our office....more