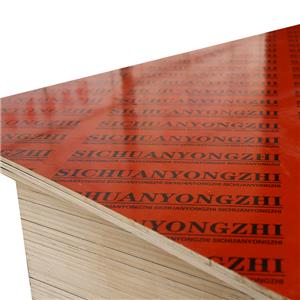

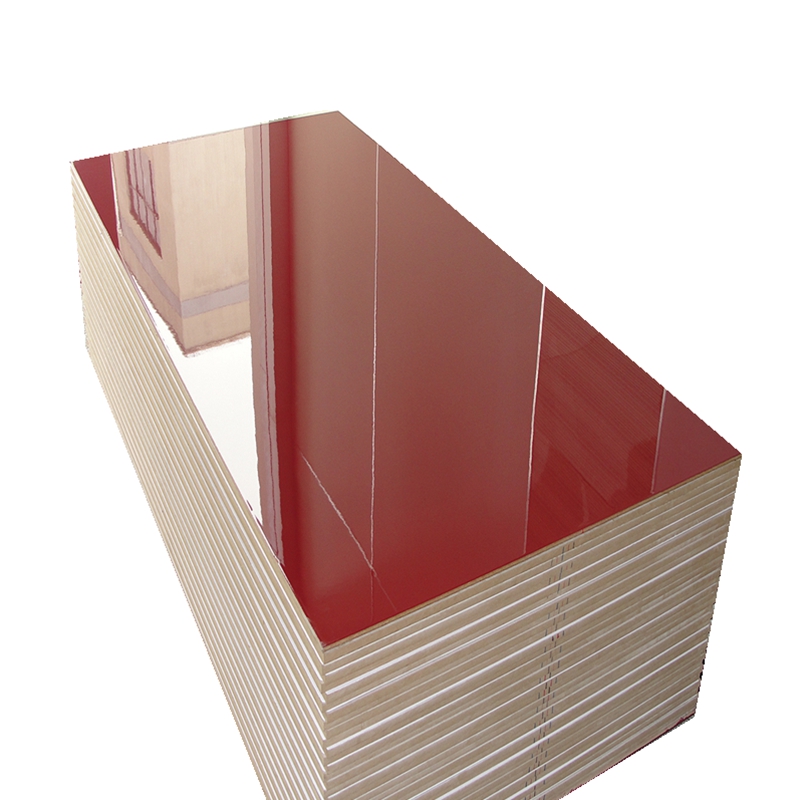

UV Coated Commercial Plywood

Brand YZY

Product origin Linyi

Delivery time Within 7~14 Days after recived deposit

Supply capacity 3000CBM/Per Month

Linyi YZY International Co.,Ltd owns four subsidiary factories and one import & export company. Headquarter in Linyi city, Shandong province, China. Founded in 1999, now, our factory covers an area of 27000 square meters with 12 plywood production lines which mainly produces Film Faced plywood, commercial plywood, formwork plywood and other wooden panels like melamine laminated plywood. The products are well sold in America, Middle East, South-America, Africa, Europe and Southeast Asia. “Quality possesses markets, and improvement gets progress” is our successful value which earned ourselves a good reputation.

3/4 inch UV prefinished baltic birch plywood for furniture

Face/Back | Okoume, Bintangor, Pencil Cedar, Keruing, Poplar, Birch, Pine, Maple, Hardwood, Ash, Oak and as your requested | |

Core: | Poplar, Hardwood, Combi, Birch, eucalypts, as your requirement. | |

Grade: | BB/BB, BB/CC, CC/CC, CC/DD,DD/EE, etc. | |

Glue: | MR/E0/E1/E2 | |

Size(mm) | 1220*2440mm,1250*2500mm,915*2135mm,915*1830mm | |

Thickness(mm) | 2.0-25.0mm | 1/8inch(2.7-3.6mm) |

1/4inch(6-6.5mm) | ||

1/2inch(12-12.7mm) | ||

5/8inch(15-16mm) | ||

3/4inch(18-19mm) | ||

Moisture | 10-15% | |

Thickness tolerance | Less than 6mm | +/-0.2mm to 0.3mm |

6-30mm | +/-0.4mm to 0.5mm | |

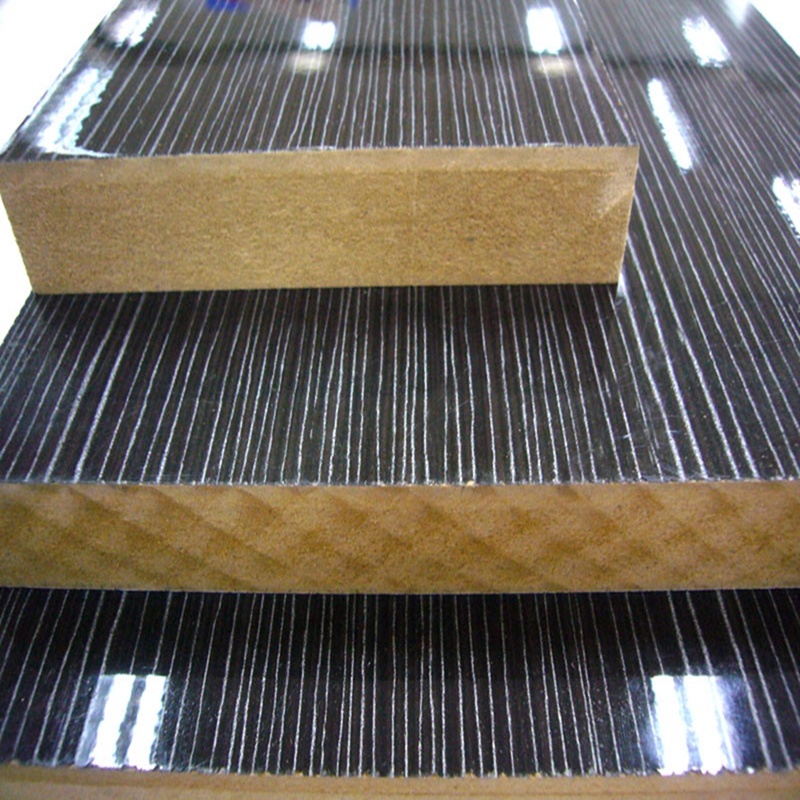

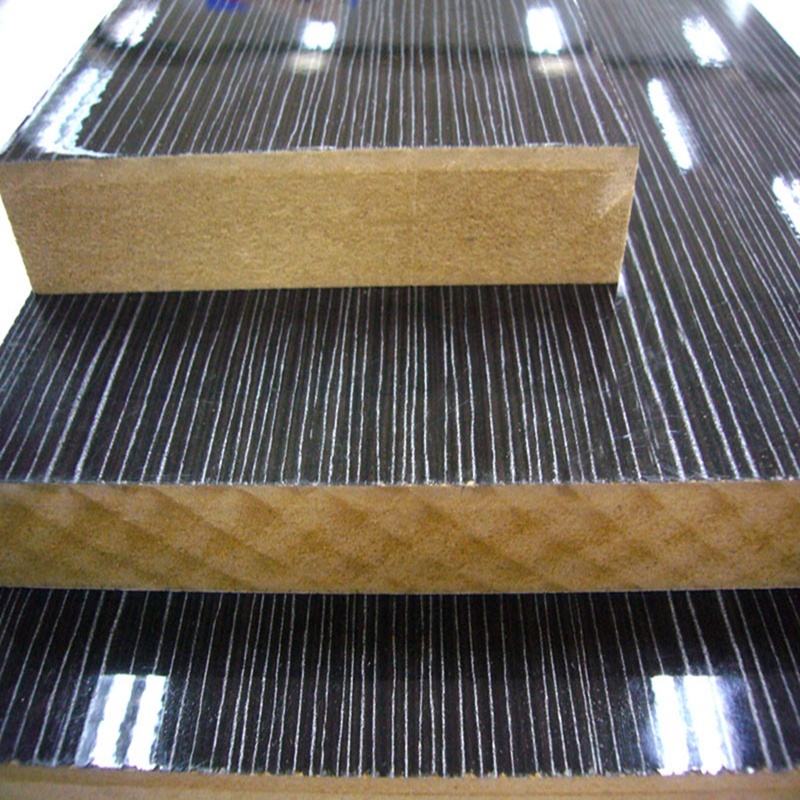

Packing | Inter packing:0.2mm plastic; Ourter packing:bottom is pallets, covered with plastic film,around is carton or plywood, strenghthen by steel or iron 3*6 | |

Quantity | 20GP | 8pallets/21M3 |

40GP | 16pallets/42M3 | |

40HQ | 18pallets/53M3 | |

Usage | Usage for making furniture or construction, package or industry, | |

Minimum Order | 1*20GP | |

Payment | TT or L/C at sight | |

Delivery Time | Within 15 days receiving deposit or original L/C at sight | |

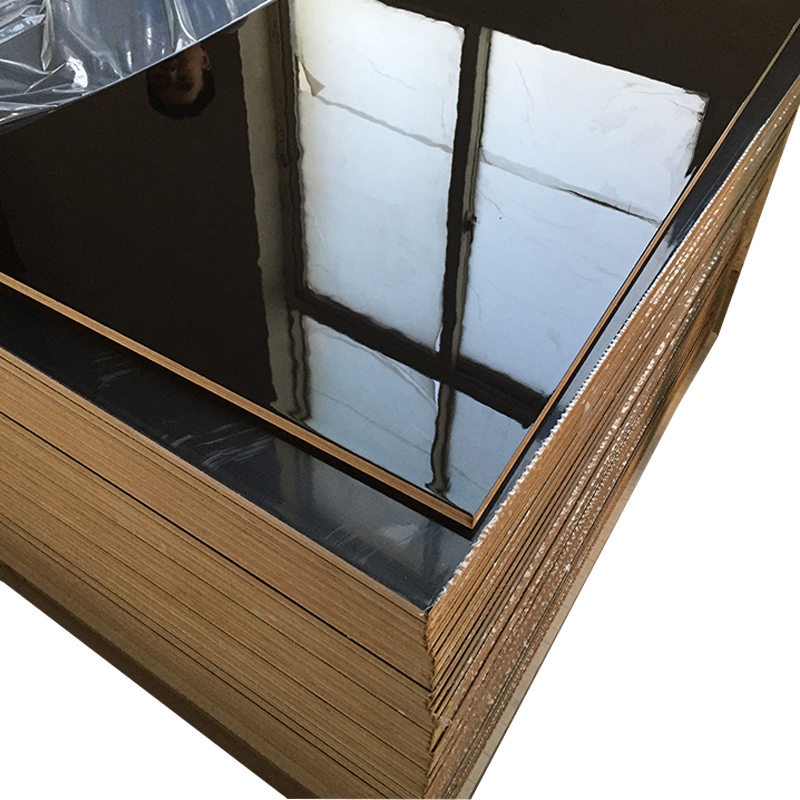

Advantages of UV Plywood

UV plywood, a high-performance wood product, is enhanced through a unique UV treatment process that offers several benefits compared to traditional plywood and other wood materials. In this process, the plywood is coated with a layer of UV paint, which is then cured and dried using a UV (ultraviolet) curing machine. This treatment results in a durable, aesthetically appealing, and highly functional product that has become increasingly popular in modern construction and interior design applications.

Here, we delve deeper into the key advantages of UV plywood and explore why it is a preferred choice for many builders, designers, and homeowners.

What is UV Plywood?

UV plywood is defined by its surface finish, which is protected and enhanced by UV treatment. The process involves applying a UV-resistant coating to the board's surface, typically using specialized paints or finishes. The coated surface is then dried using UV curing equipment, creating a high-gloss, smooth, and visually appealing finish. This unique treatment not only improves the plywood's appearance but also enhances its durability, making it resistant to wear and tear.

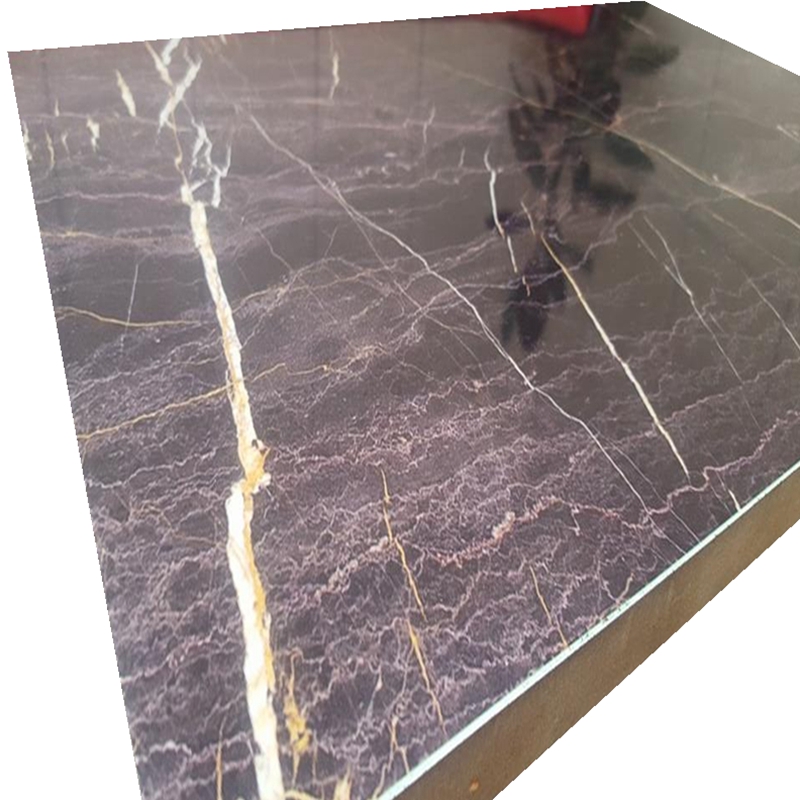

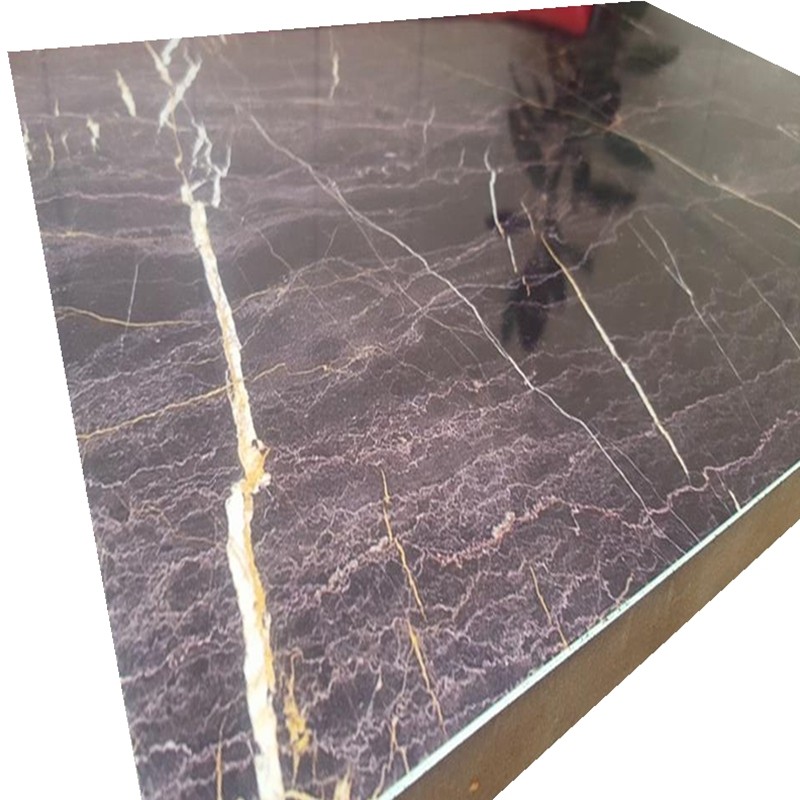

The UV plywood production process is versatile and can be applied to various board types, including standard plywood, calcium silicate boards, and other engineered wood products. Due to its superior surface treatment and durability, UV plywood is considered an ideal board for applications where aesthetics, performance, and longevity are critical.

Six Key Advantages of UV Plywood

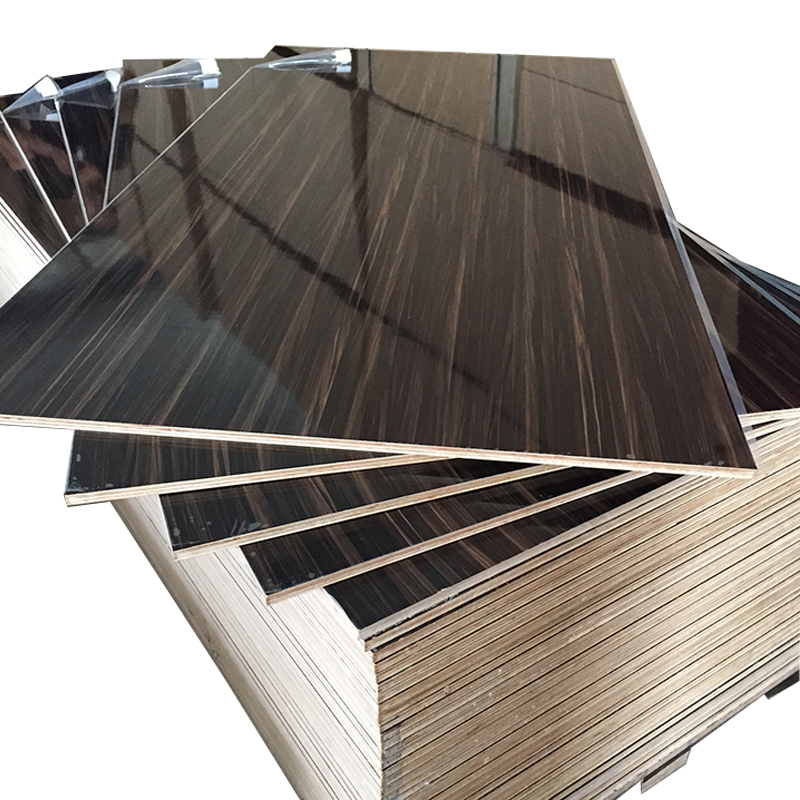

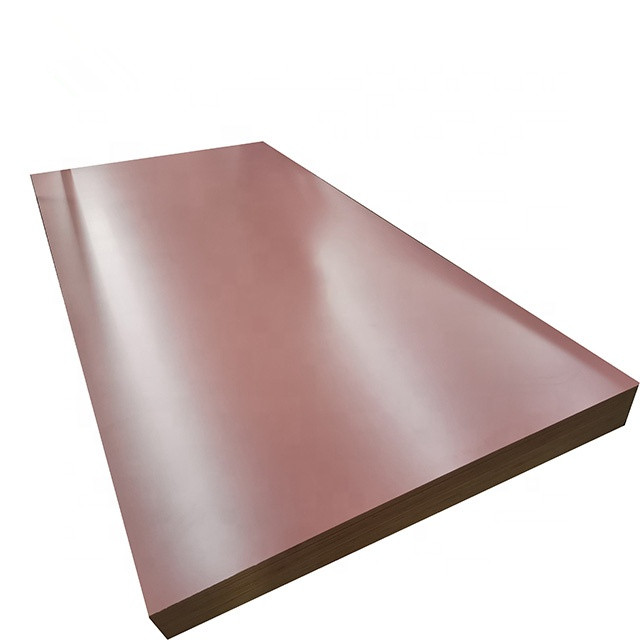

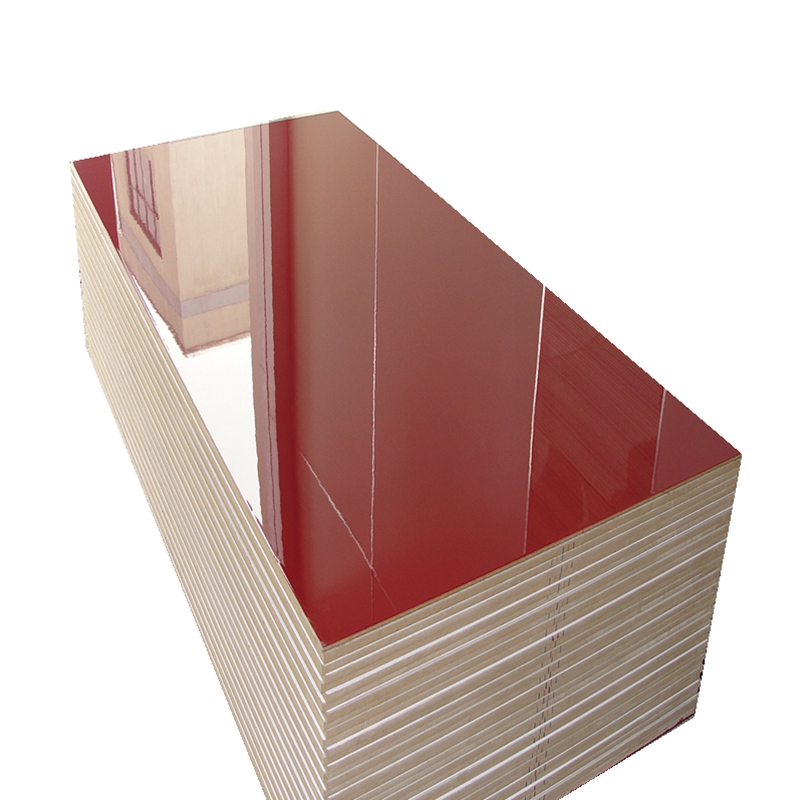

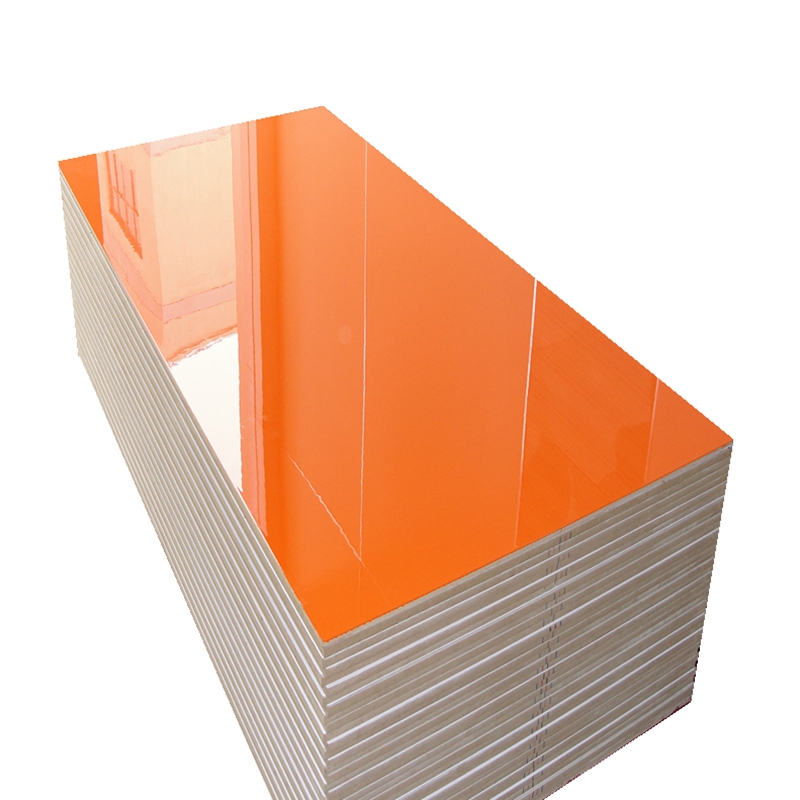

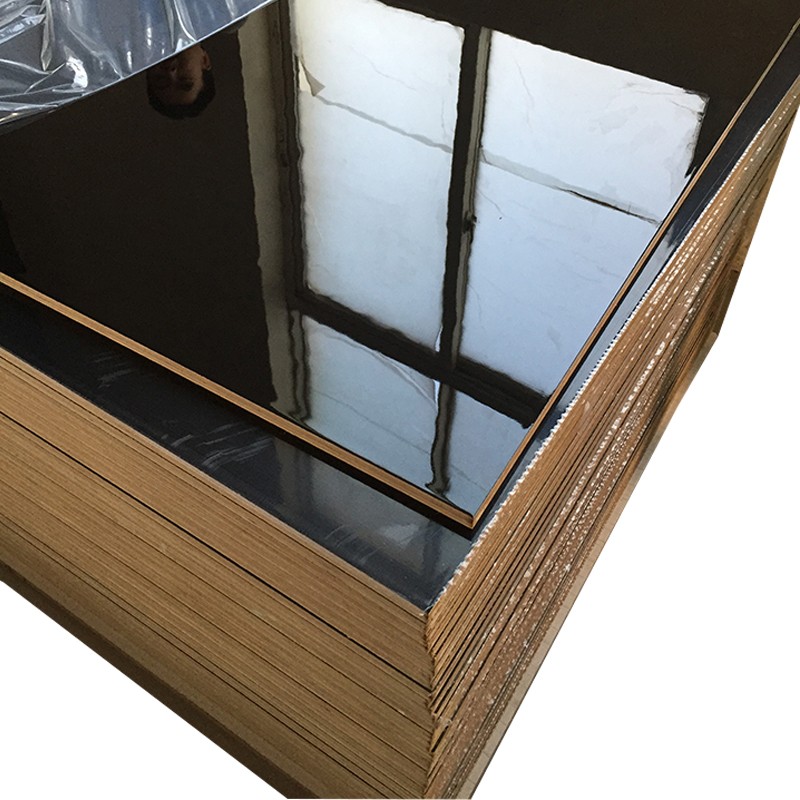

Bright Color and High Gloss:

One of the standout features of UV plywood is its vibrant color and high-gloss finish. The UV coating enhances the wood’s natural grain and color, creating a surface that is visually striking and reflective. This bright appearance gives any space a modern, polished look, making it an ideal choice for interior applications like cabinets, furniture, and wall panels.

High Surface Hardness and Scratch Resistance:

UV plywood is known for its high surface hardness, which significantly improves its resistance to scratches, dents, and abrasions. This makes it a practical option for high-traffic areas or surfaces prone to wear and tear, such as kitchen cabinets, tabletops, and shelving units. The hardness of the UV coating also helps maintain the integrity and appearance of the plywood over time.

UV Paint Resistance to Oxidation, Yellowing, and Fading:

The UV coating on the plywood protects it from the harmful effects of sunlight and environmental exposure. UV plywood is highly resistant to oxidation, yellowing, and fading, ensuring that its color and gloss remain intact even after prolonged use. This property is particularly advantageous in applications where consistent aesthetics are essential, such as commercial interiors, retail displays, and residential spaces.

Ease of Cleaning and Maintenance:

The smooth and non-porous surface of UV plywood makes it exceptionally easy to clean and maintain. The UV coating prevents dust, dirt, and grease from penetrating the surface, allowing for quick and hassle-free cleaning. This is particularly beneficial for applications like kitchen cabinetry, where surfaces are often exposed to grease and spills.

Environmental Safety and Non-Toxic Properties:

UV plywood is manufactured using environmentally friendly UV paints, which are free from harmful chemicals and toxins. These paints do not release volatile organic compounds (VOCs) or other hazardous emissions, making UV plywood a safe and eco-friendly option for indoor use. Its non-toxic properties make it suitable for residential spaces, including children’s rooms, kitchens, and living areas.

Shorter Production Cycle and Easy Repair:

Compared to traditional finishing methods like baking varnish, UV finishing has a shorter production cycle. The UV curing process is faster, more efficient, and easier to control, resulting in a quicker turnaround time. Additionally, UV plywood is easy to repair if damaged. Matching the color and finish is relatively straightforward, ensuring that repairs blend seamlessly with the original surface.

Additional Benefits of UV Plywood

Apart from its primary advantages, UV plywood offers several other benefits that make it a versatile material for various applications:

Long Service Life: The UV coating significantly extends the lifespan of the plywood, reducing the need for frequent replacements and maintenance.

Chemical Resistance: The UV surface is resistant to many chemicals and solvents, further enhancing its durability in different environments.

Cost-Effective Solution: Despite its superior properties, UV plywood is competitively priced, making it an attractive option for cost-conscious projects.

Applications of UV Plywood

Given its properties, UV plywood is widely used in numerous applications:

Cabinetry and Furniture: The high-gloss, durable surface makes UV plywood ideal for modern kitchen cabinets, wardrobes, and custom furniture pieces.

Interior Wall Panels: UV plywood can be used for decorative wall panels, adding a touch of sophistication and elegance to interior spaces.

Commercial Interiors: Its vibrant appearance and durability make it suitable for commercial interiors, such as retail spaces, showrooms, and offices.

Countertops and Tabletops: The scratch-resistant and easy-to-clean surface is perfect for countertops and tabletops in kitchens, dining areas, and workspaces.

Conclusion

UV plywood is a high-quality material that offers a range of benefits, from its aesthetic appeal to its durability and ease of maintenance. Its unique UV coating process makes it an excellent choice for applications that demand both functionality and style. Whether for cabinetry, furniture, or decorative wall panels, UV plywood is a versatile and reliable option that can enhance any project with its vibrant color, durability, and long-lasting performance.

Application Case

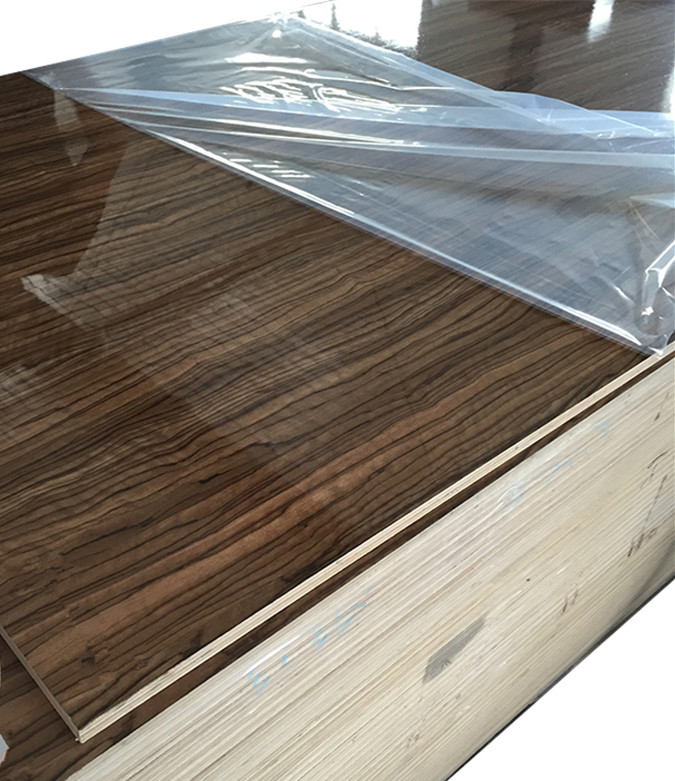

Packaging & Shipping

Inner packing: Inside pallet is wrapped with a 0.20mm plastic bag

Outer packing: Pallets are covered with 3mm package plywood or carton and then steel tapes for strengthenin