Finger Joint WBP GLUE Film Faced Plywood

Brand YZY

Product origin China

Delivery time Within 2-3 weeks upon down payment or upon opening of L/C

Supply capacity 3000 Cubic Meter/Cubic Meters/month

Film faced plywood is one of our main products.the Grade from finger jointed core to Full birch core.Re-using times can be from 2-50 times according to different raw materials.

Product Description

please check our film faced plywood advantages:

1.No wapping, no fracture,not out of shape, it can stay 24hours in boiling water.

2.Good performance and more turnover use time.

3.It is easy to take off the membrane;Time is only 1/7 of the steel mould.

4.Make the surface of concrete more smooth and beautiful,so it can be easy to make decoration and it also deduct the processing of plastering.

5.This can moderate and contact 30% time for a project.

6.Corrosion resistant and it will not pollute the surface of concrete.

7.It is good to keep performance warm,ia favorable to make construction in winter.

8.Products can be made into warping plywood

9.It is better to nail,saw,drill than bamboo and steel mould, it can be processed into different types.

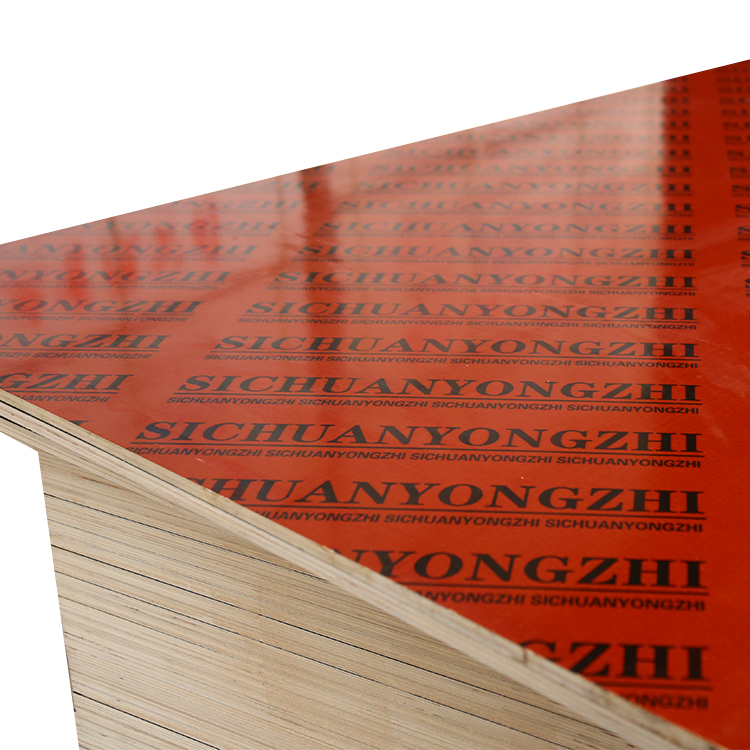

| Name | Finger Joint Core Film Faced Plywood | |

| Brand | YZY | |

| Size | 1220x2440mm or upon request | |

| Thickness Tolerance | 4-25mm or upon request | ±0.5mm |

| Core | Finger Joint Core | |

| Edge | Sealed with water proof paint, paint color can be upon request | |

| Film options: | Domestic Black or Brown film | |

| Glue | Mr, Melamine, Phenolic WBP | |

| Formaldehyde Emission Standards | Carb,E0,E1,E2 | |

| Moisture | 6%-10% at the time of shipment | |

| Usage | Real estate construction /formwork panel | |

| Package | Outer packing: pallets are covered with plywood or carton boxes and strong steel belts | |

| Certification | CE, ISO,FSC Certified,CARB | |

| Delivery time | Within 2-3 weeks upon down payment or upon opening of L/C | |

| Min Order | 1*20'ft | |

| PAYMENT TERM | TT or L/C | |

| Supply ability | 10000 M3/per month | |

| MARK: | Depend customer | |

Understanding Finger Joint Plywood

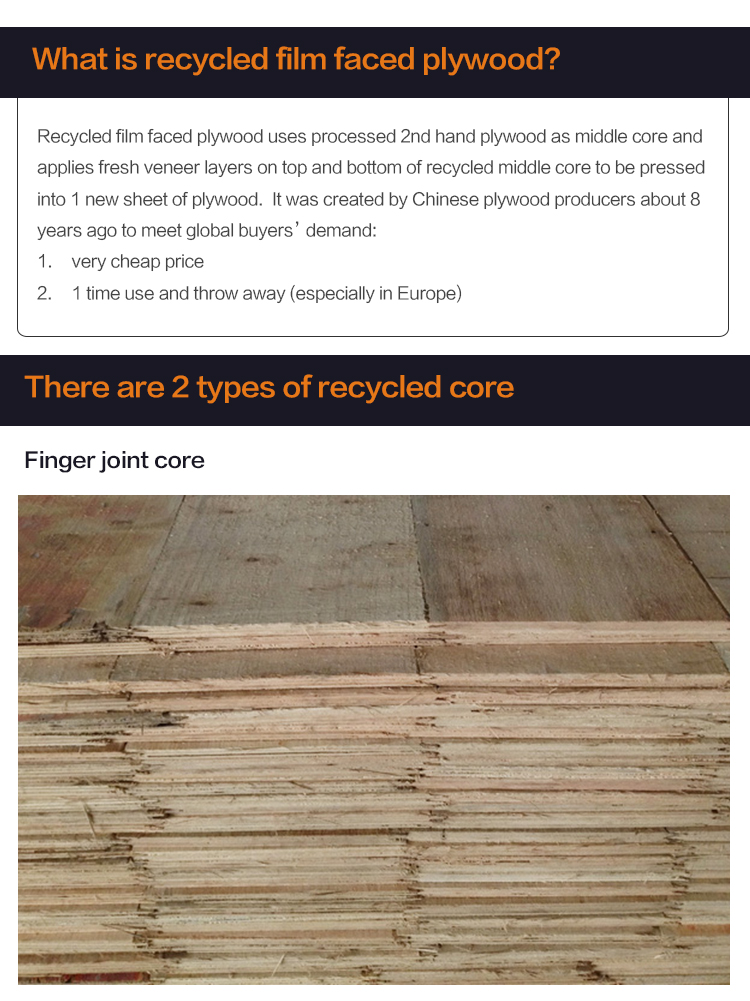

What is Finger Joint Plywood?

Finger joint plywood is a specialized type of engineered wood product that is created by joining shorter pieces of wood together using a finger joint technique. This method involves cutting interlocking "fingers" on the ends of each piece, allowing them to fit together snugly and be bonded with adhesive. The result is a long, continuous panel that combines the strengths of solid wood with the versatility of plywood.

Key Characteristics of Finger Joint Plywood

Strength and Stability: The finger jointing process enhances the structural integrity of the plywood, making it more resistant to warping and splitting compared to traditional plywood. This stability is particularly beneficial in applications where dimensional stability is crucial.

Sustainable: Finger joint plywood is often made from smaller, sustainably sourced pieces of wood, reducing waste and making it an environmentally friendly choice. It allows manufacturers to use less desirable or smaller logs that might otherwise go unused.

Cost-Effective: By utilizing smaller pieces of wood, finger joint plywood can be more economical than solid wood alternatives. This makes it an attractive option for builders and manufacturers looking to minimize costs without compromising quality.

Versatile Applications: Finger joint plywood can be used in a variety of applications, including furniture, cabinetry, and interior construction. Its smooth surface and ability to be easily finished or painted make it suitable for both functional and aesthetic uses.

Customization: The length and thickness of finger joint plywood can be customized to meet specific project requirements, providing flexibility for different construction and design needs.

Benefits of Finger Joint Plywood

Reduced Waste: The process of finger jointing allows for efficient use of wood, making it a sustainable choice.

Improved Aesthetics: With a smooth surface, finger joint plywood can be finished in various ways, enhancing its visual appeal in furniture and cabinetry.

Ease of Handling: The uniformity in size and strength makes finger joint plywood easy to handle and work with on job sites.

Conclusion

Finger joint plywood is a versatile and eco-friendly alternative to solid wood and traditional plywood. Its unique construction method offers enhanced strength and stability, making it suitable for a wide range of applications. Whether for building furniture, cabinetry, or structural components, finger joint plywood delivers quality and performance while being mindful of environmental sustainability.

Packaging & Shipping

Linyi YZY Interantional Trade Co,.Ltd,

Adress:Room 2204 Dongfang Jiayuan Building , Lanshan District,Linyi City Shandong Province,China 27600

Construciton Plywood Supplier |www.sowowood.com |

Skype:yzy@yzylinyi.com |Wechat:17753974353|What'sApp/Viber:+86 15094723345