Poplar Combi Brown Film Faced Plywood

Brand YZY

Product origin Linyi

Delivery time Within 15 days after order confirmed

Supply capacity 1000 cbm/month

Product Name: Film faced plywood for building construction

Sheet size: 1220x2440mm, 2400x1200mm, 1800x1200mm, 1250x2500mm.

Thickness: 9mm~21mm

Core: Birch, Eulcayptus, Poplar, pine, or combi

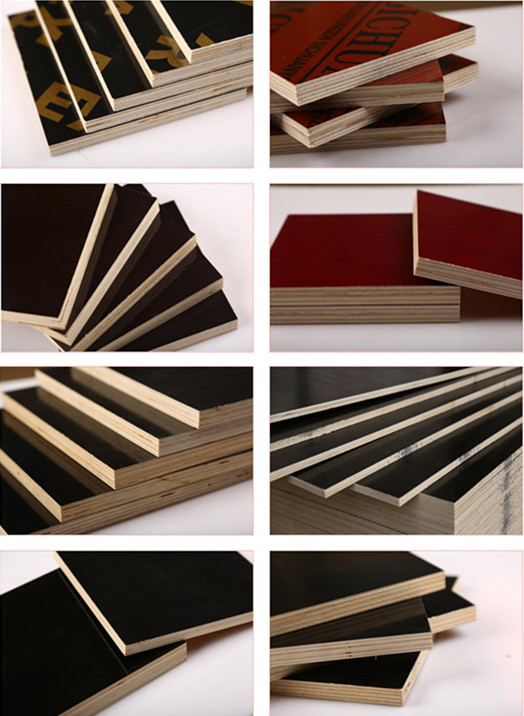

Film: Black, Brown, Red or Anti-slip film

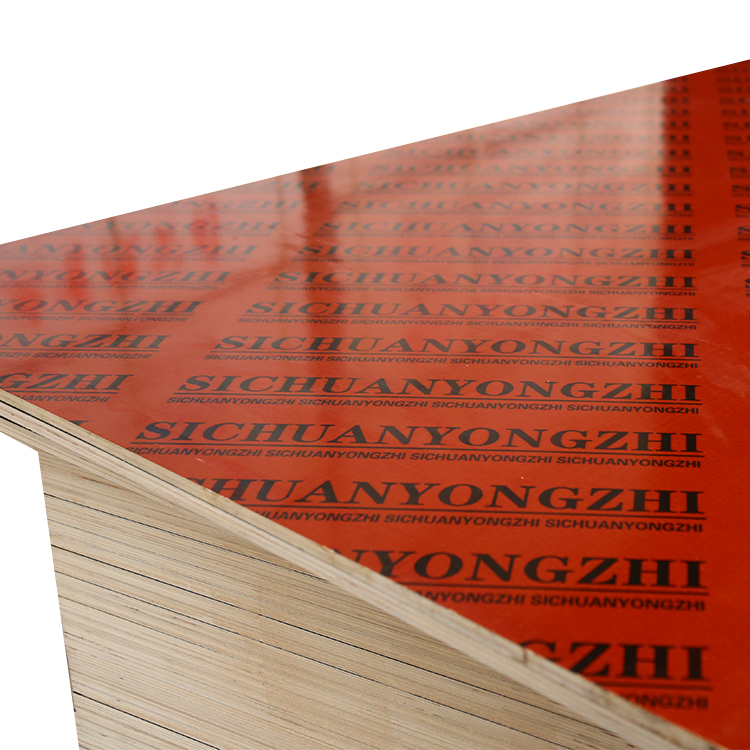

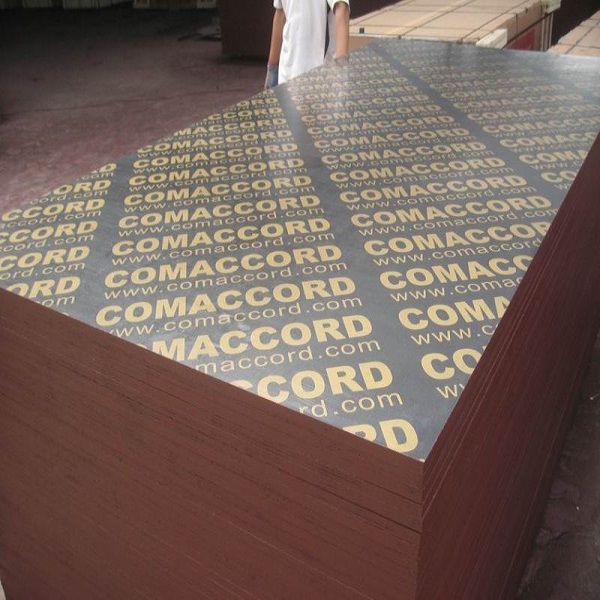

Edge: Edges sealed with waterproof print (color is optional)

Film faced plywood construction | |

Size | 1220x2440mm, 1250x2500mm, 1200x1800, 1200x2400mm, etc. |

Core | Birch, Eucalyptus, poplar, Pine, etc. |

Face & back | Black, Brown , Red or Anti - Slip film |

Edges seal | Edges sealed with waterproof Print (color is optional) including Silicon to make sure the products airtight. |

Packing | Inner with plastic bag, outer is covered with the carton and plywood, and steel tape for strength |

Payment | TT or L/C at sight |

Application | Concrete formwork . Floors for trailers. decks, retaining walls, bridges,etc. |

Advantage | 1. Reuse times: more than 10 times 2. Wear-resistance: The 0.5mm PP film performs well in wear and corrosion resistance 3. The surface of the cement: the surface is very smooth, glossy & uniform from the first time to the end |

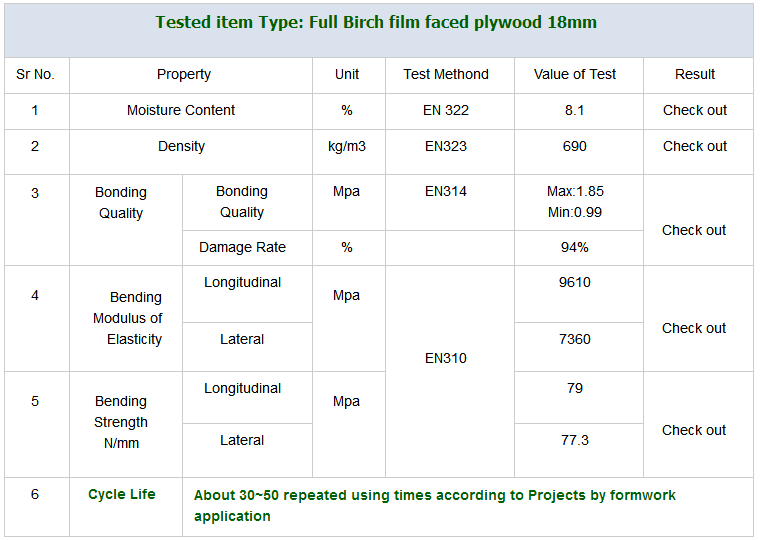

Technical Specification

Detailed Images

Advantages of Poplar Film Faced Plywood

Poplar film faced plywood stands out as a practical and economical choice in the construction industry, particularly for shuttering and furniture applications. Here are the key advantages of this versatile material:

1. Durability

Poplar film faced plywood is exceptionally durable, making it suitable for repeated use. High-quality poplar plywood can be reused over 10 to 20 times, while medium-grade options offer 5 to 8 uses. Economical-grade variants still provide decent longevity, with 2 to 4 uses, making it a cost-effective choice for various projects.

2. Cost-Effectiveness

Poplar grows quickly compared to other hardwoods, leading to a more abundant supply and lower prices. This affordability combined with good performance makes poplar film faced plywood an attractive option for budget-conscious projects without sacrificing quality.

3. Specifications and Customization

Poplar film faced plywood comes in various grades (A/A, B/B, and economical) and is available in different sizes and thicknesses (4mm to 30mm). Customers can choose from a range of films (black or brown) and core grades (from A+ to finger-jointed), allowing for tailored solutions based on project requirements.

4. Superior Appearance and Quality

The A/A grade poplar film faced plywood has an excellent finish, with a flat and smooth surface that is visually appealing. Its core can vary from high-quality whole veneers to economical finger-jointed options, ensuring there is a suitable choice for any application.

5. Versatile Applications

This plywood is ideal for various uses, including concrete shuttering, building materials, and high-quality furniture production. Its durability and water-resistant properties make it suitable for both indoor and outdoor applications.

6. Global Demand

Poplar film faced plywood enjoys a strong export market, with around 60% going to Europe and 40% to the Middle East and other regions, highlighting its global appeal and reliability in construction projects.

Conclusion

Poplar film faced plywood combines durability, cost-effectiveness, and versatility, making it a preferred choice for numerous construction applications. Its robust nature, ease of use, and aesthetic qualities allow it to meet a wide range of project requirements while remaining budget-friendly. Whether for concrete formwork or furniture, poplar film faced plywood continues to be a valuable resource in the construction industry.

Packing & Delivery

Linyi YZY Interantional Trade Co,.Ltd,

Adress:Room 2204 Dongfang Jiayuan Building , Lanshan District,Linyi City Shandong Province,China 27600

Construciton Plywood Supplier |www.sowowood.com |

Skype:yzy@yzylinyi.com |Wechat:17753974353|What'sApp/Viber:+86 15094723345