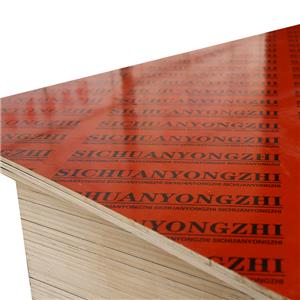

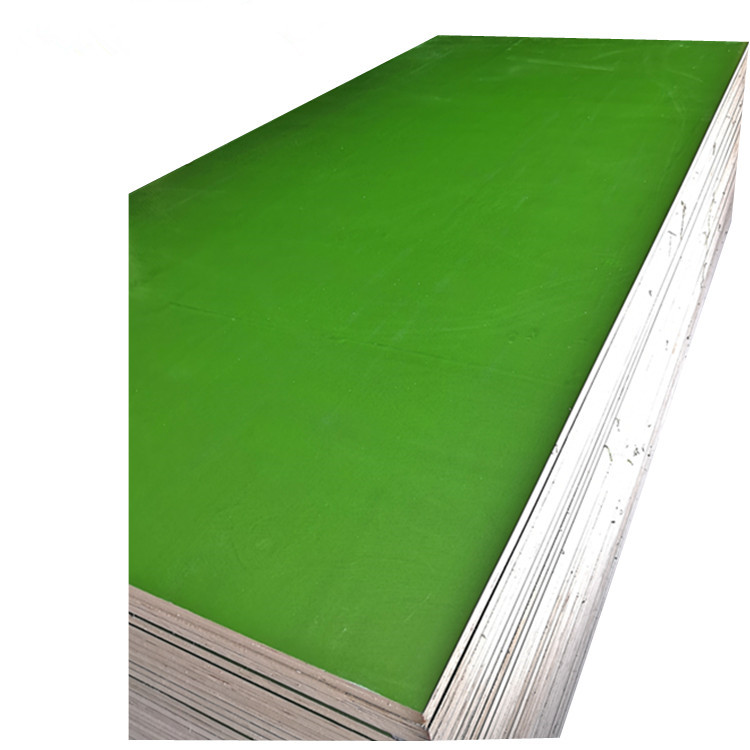

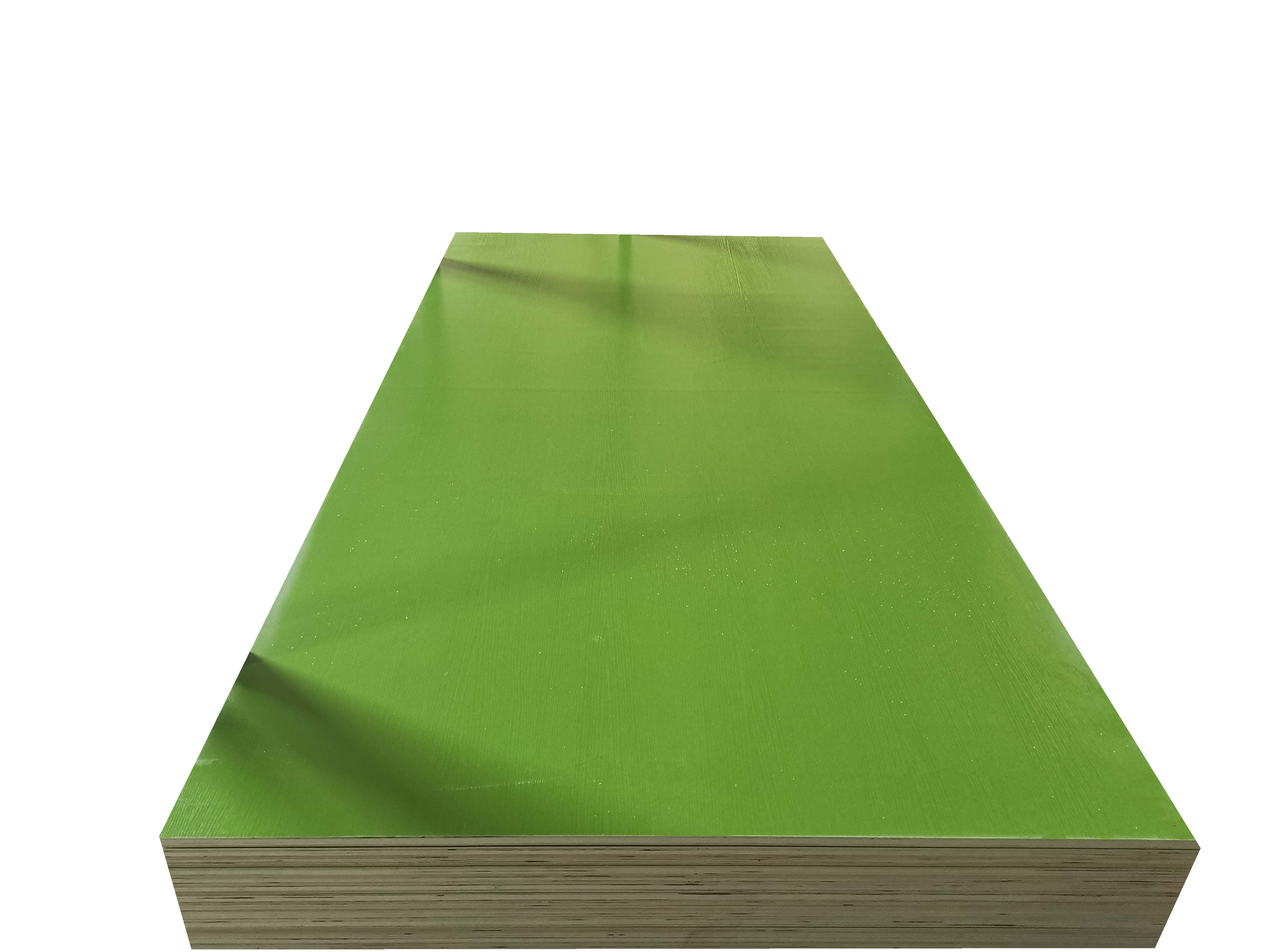

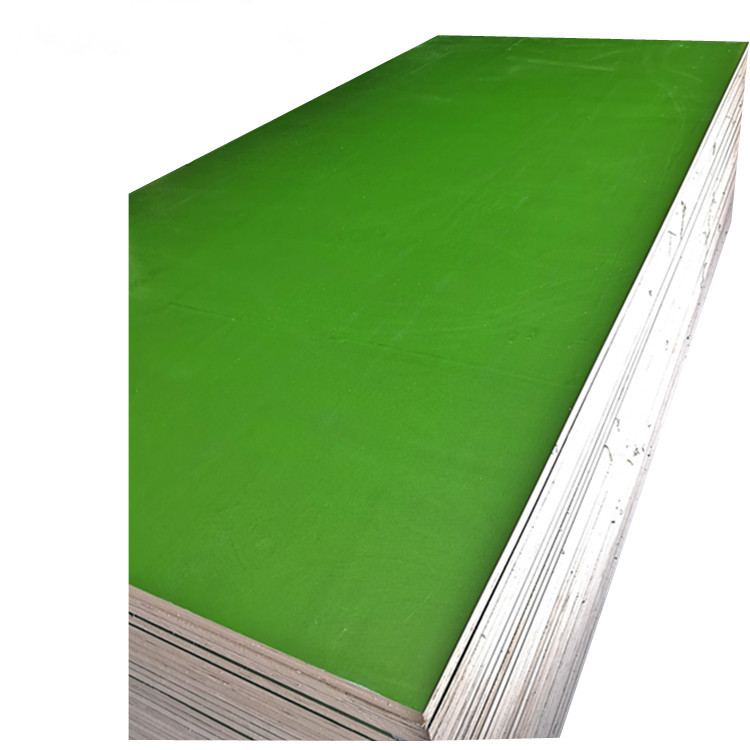

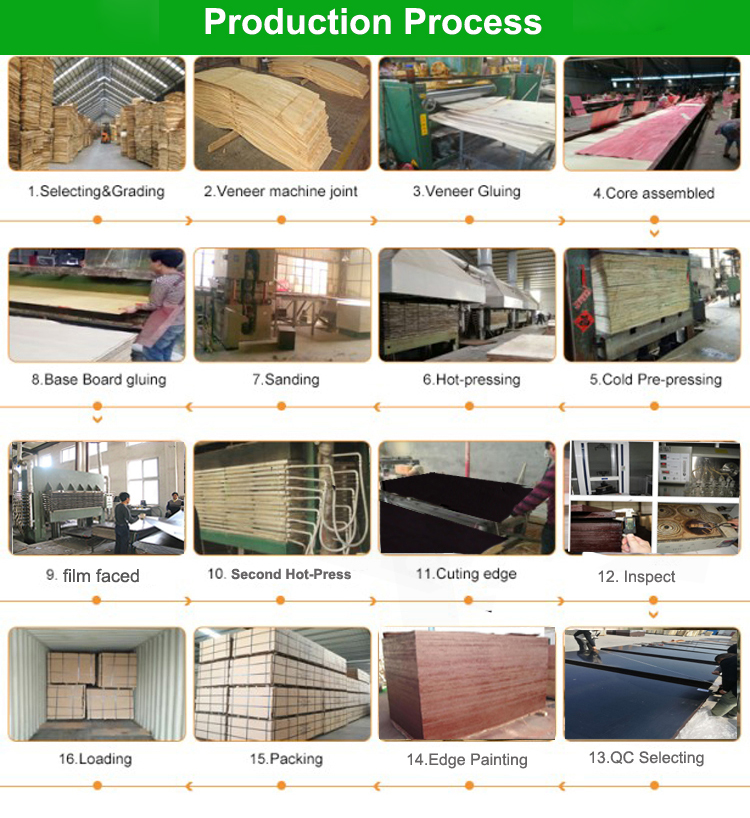

Green Plastic Polyester Film Faced Plywood

Brand YZY

Product origin Linyi

Delivery time Within 2-3 weeks upon down payment or upon opening of L/C

Supply capacity 10000 Piece/Per Day

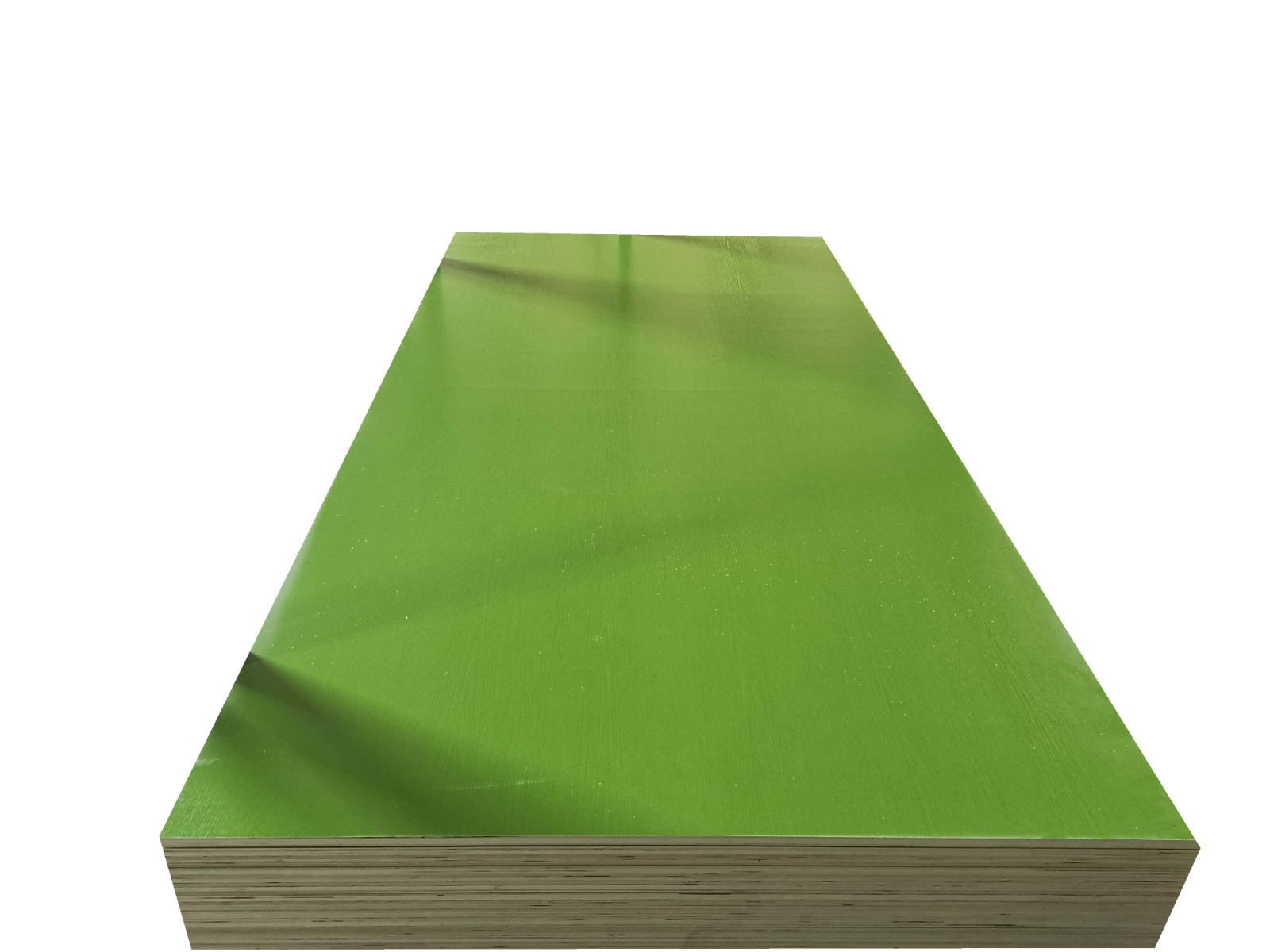

High Quality Green Plastic FILM FACED PLYWOOD

1. SIZE: 1220*2440mm or customer design

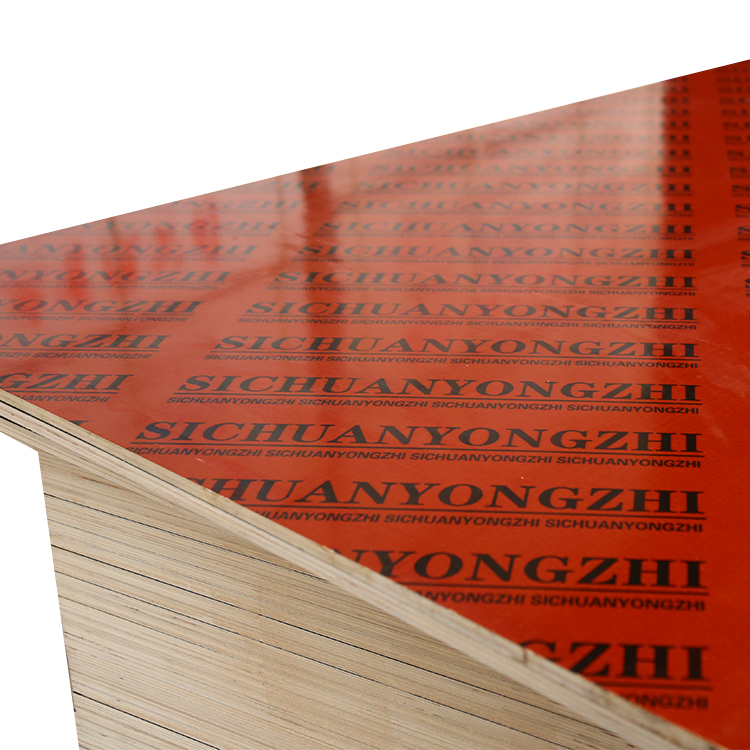

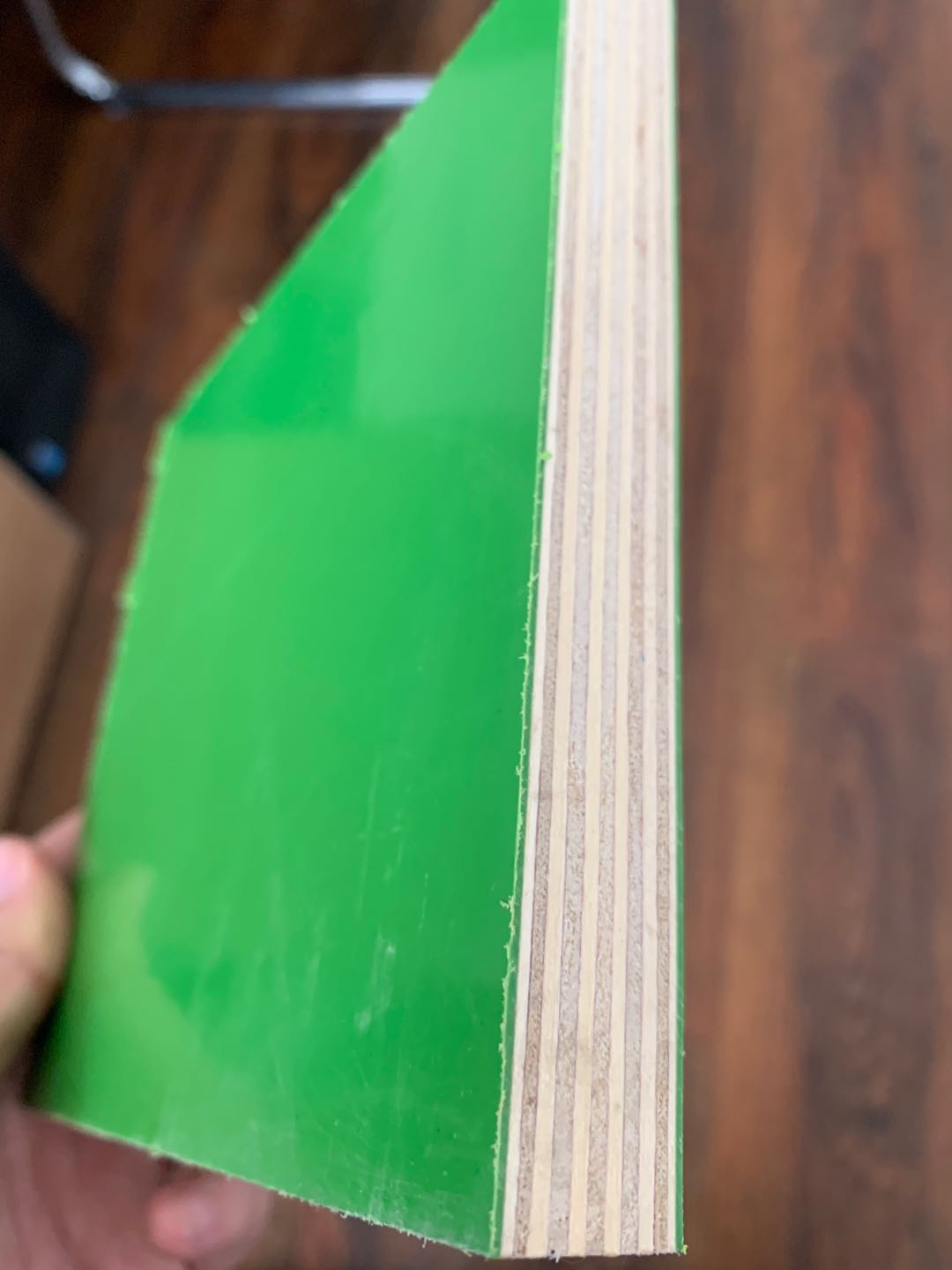

2. Face/Back: Green Plastic(can print request logo depend customer)

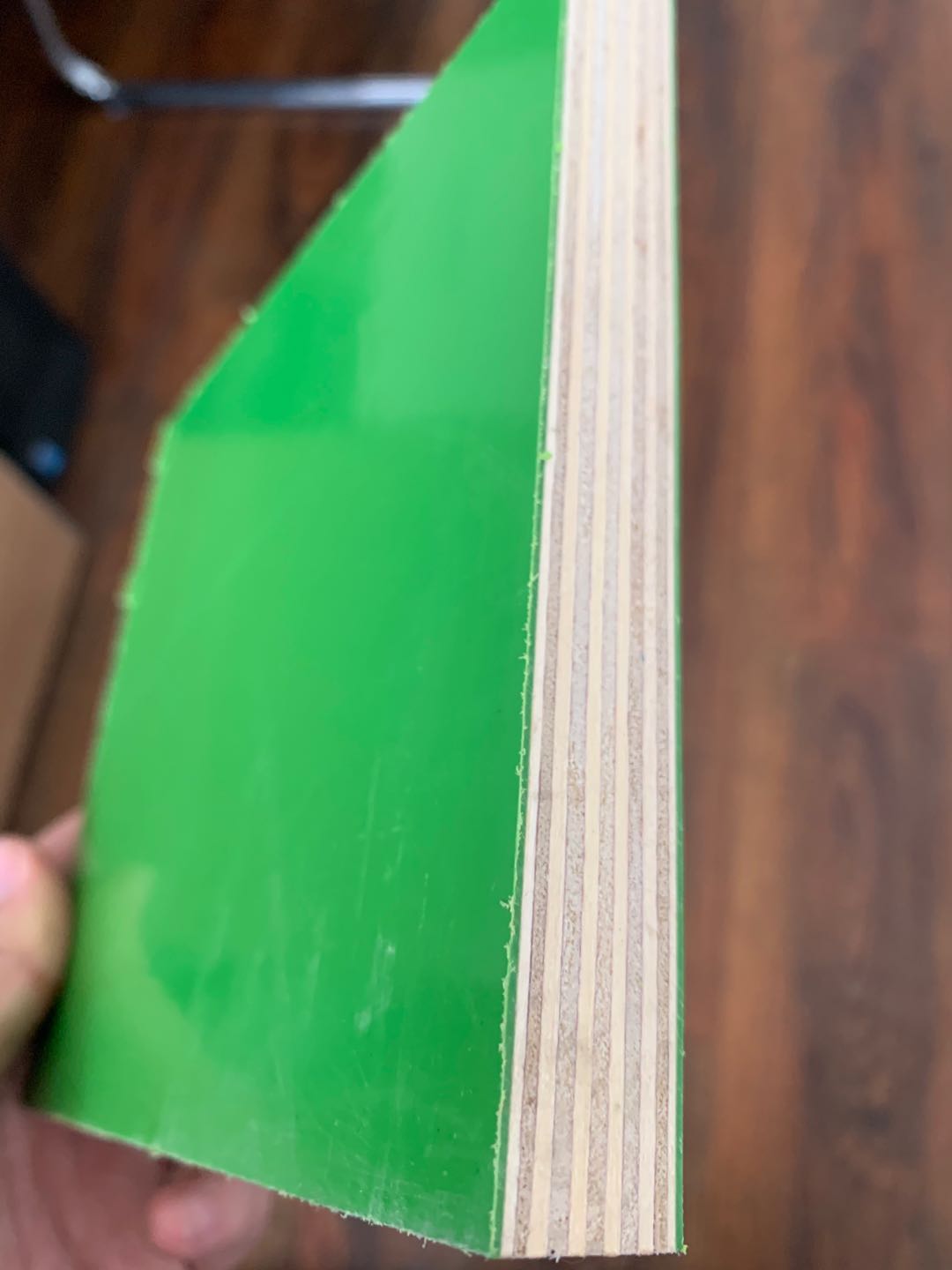

3. Thickness: 12~21mm

4. Core materials: poplar, combi, birch, eucalyptus, etc.

5. Glue: melamine, wbp, phenolic, etc.

6. Usage: construction or concrete

Production Specifications | |

Name | Green Plastic Concrete Formwork Board Film Faced Plywood |

Size | 1220*2440mm(4'*8'),900*2100mm ,1250*2500mm or upon request |

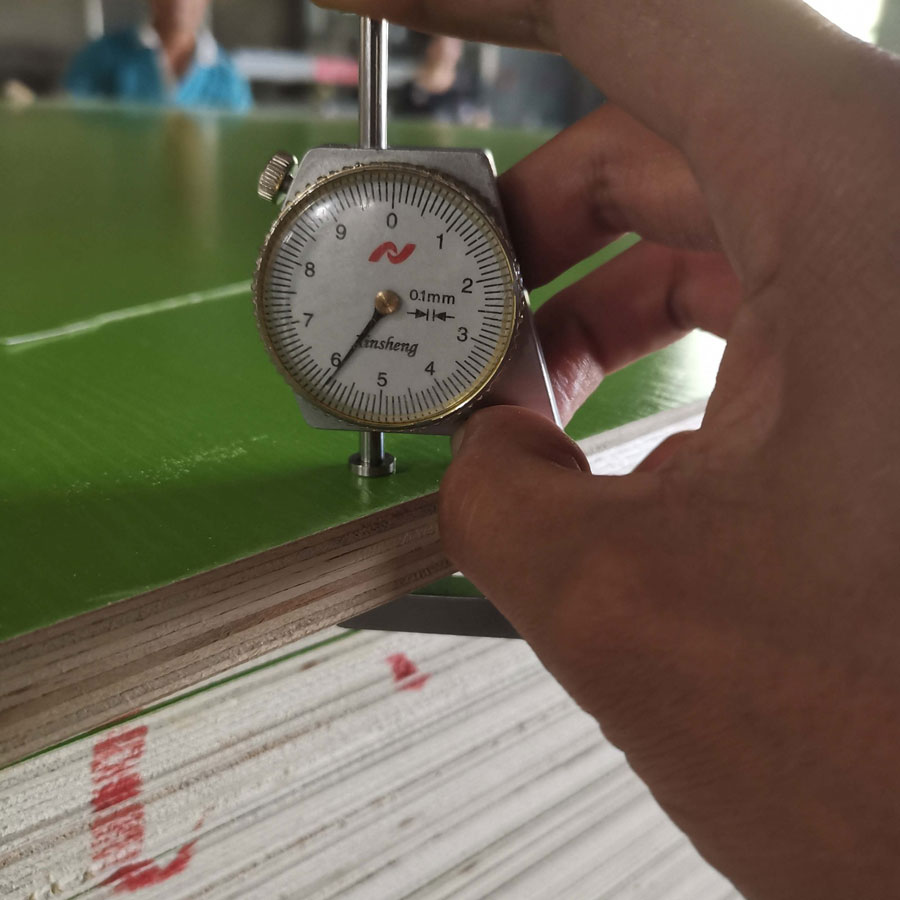

Thickness | 9mm ,12mm ,15mm,18mm ,21mm ,24mm or upon request |

Thickness Tolerance | +/-0.5mm |

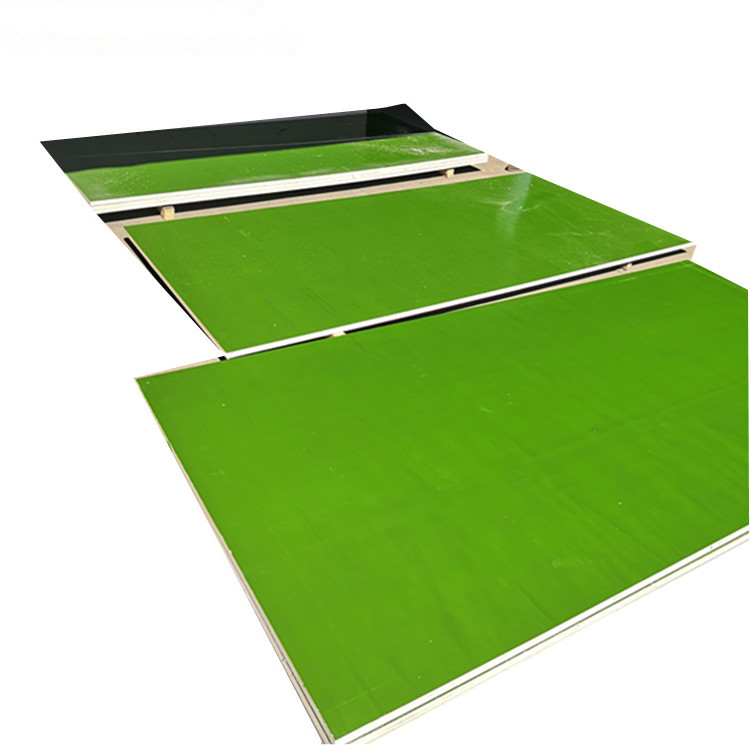

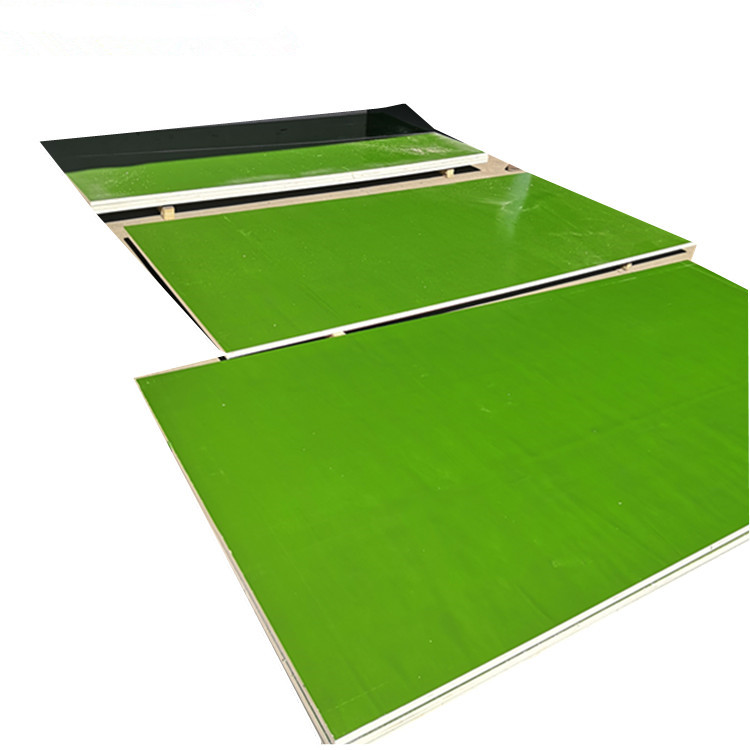

Face/Back | Green plastic Film or black ,brown Red ,yellow Film or Dynea dark brown film, Anti Slip film |

Core | Poplar, Eucalyptus, Combi, Birch or upon request |

Glue | Phenolic ,WBP ,MR |

Grade | One Time Hot press / Two Time hot press / Finger-Joint |

Certification | ISO ,CE,CARB ,FSC |

Density | 500-700kg/m3 |

Moisture Content | 8%~14% |

Water Absorption | ≤10% |

Standard Packing | Inner Packing-Pallet is wrapped with 0.20mm plastic bag Outer Packing-pallets are covered with plywood or carton boxes and strong steel belts |

Loading Quantity | 20’GP-8pallets/22cbm, 40’HQ-18pallets/50cbm or upon request |

MOQ | 1x20’FCL |

Payment Terms | T/T or L/C |

Delivery Time | Within 2-3 weeks upon down payment or upon opening of L/C |

Features | 1)Transference to concrete is set up very easily 2)Waterproof, Wear-resistant, anti-cracking 3).Environmentally friendly |

The Advantages of Film Faced Plywood: A Durable Choice for Various Applications

Film faced plywood stands out as a highly durable and versatile material, particularly known for its water resistance and long-lasting performance. This engineered wood product, often referred to as "water-boiled" plywood or formwork plywood, is treated to withstand the rigors of outdoor environments, making it an ideal choice for a wide range of applications.

Key Benefits of Film Faced Plywood

Superior Water Resistance

One of the most significant advantages of film faced plywood is its exceptional resistance to water. Unlike traditional wood veneer faced plywood, it features a smooth, resin-treated surface that repels moisture, ensuring that the core remains protected even in wet conditions. This waterproofing extends to the edges, which are coated to prevent water damage. As a result, film faced plywood is suitable for outdoor applications, from decking to outdoor formwork systems.Durability and Wear Resistance

Film faced plywood is engineered for durability, making it resistant to wear and tear. This makes it a perfect choice for constructing furniture and shelves that need to withstand daily use. Its high-quality wood and advanced manufacturing processes contribute to its robustness, allowing it to endure harsh environmental conditions without losing structural integrity.Versatile Applications

The adaptability of film faced plywood allows it to be used in a variety of settings, including both outdoor and indoor environments. It is ideal for construction projects such as swimming pools, playgrounds, sports arenas, and even agricultural structures. Its waterproof qualities make it particularly effective in settings where moisture is a concern, such as boat building and dam construction.Ease of Use

Another notable benefit of film faced plywood is its ease of handling and installation. The film-coated surface provides a smooth, mirror-like finish that enhances the aesthetic appeal of any project. Available in various thicknesses, ranging from 6.5 mm to 40 mm, it can be tailored to meet specific construction needs. Additionally, its resistance to degrading chemicals means that it can be reused multiple times, further maximizing its value.Cost-Effectiveness

Film faced plywood not only saves time and effort during installation but also offers significant cost savings over time. Its durability reduces the frequency of replacements, making it a financially smart choice for both residential and commercial projects. The ability to withstand the elements while maintaining performance characteristics makes it a preferred material for builders and designers alike.

Conclusion

Film faced plywood is a remarkable material that combines durability, versatility, and aesthetic appeal. Its superior water resistance, coupled with the ability to resist moisture and fungal attacks, makes it an excellent option for both indoor and outdoor applications. Whether for construction, furniture, or specialized projects like boat building, film faced plywood delivers exceptional performance and longevity. With its numerous advantages, it is easy to see why this material continues to gain popularity across various industries. Consider film faced plywood for your next project and enjoy its endless benefits!

Linyi YZY Interantional Trade Co,.Ltd,

Adress:Room 2204 Dongfang Jiayuan Building , Lanshan District,Linyi City Shandong Province,China 27600

Construciton Plywood Supplier |www.sowowood.com |

Skype:yzy@yzylinyi.com |Wechat:17753974353|What'sApp/Viber:+86 15094723345